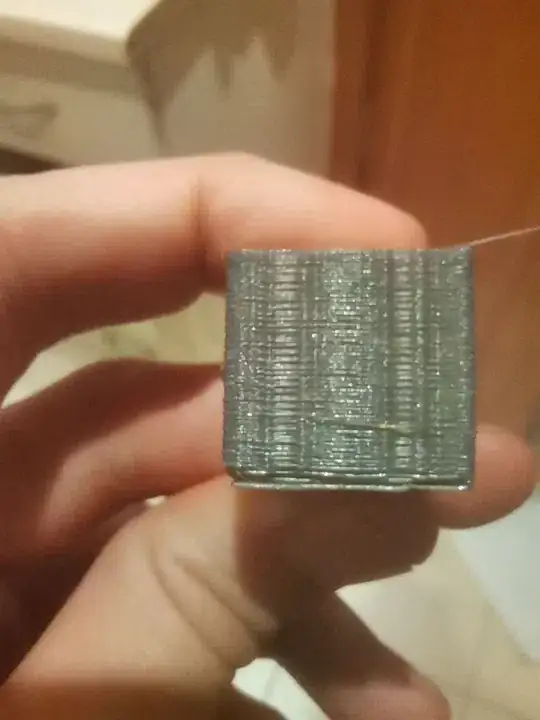

I'm facing weird "pillars" of underextrusion on outer walls of my XYZ test cube.

On the pictures below I`ve printed PLA test cubes with a 0.4 mm nozzle, 0.2 mm height and 210/50 °C hotends/bed temperature.

Gaps are appearing in walls parallel to both X and Y sides. The pictured side is parallel to Y face.

I'm slicing with Cura, my printer is a homebuilt around Anycubic Kossel with Marlin 2.0 onboard.

What have I tried already:

1. Temperature from 190 to 210 °C

2. Retraction from none to 6 mm 60 mm/sec

3. Tuning down Jerk in Marlin from [10,10,0.3] to [5,5,0.3]

4. Tuning down acceleration from 3000 to 1000

5. Tuning print speed from 60 to 30 mm/sec

6. Checking belts, nozzle and extruder.

Now I just ran out of ideas. Delta is calibrated by G33 autotune. Mechanics looks just fine. What am I missing?

UPD1: tried removing combing - it did not help. But I noticed that my printer accelerates strangely at this parts

UPD2: could it be stuttering? I have 320 segments per second with block buffer size of 8 bytes(?)

UPD3: lowering segments count to 120 and raising block size to 32