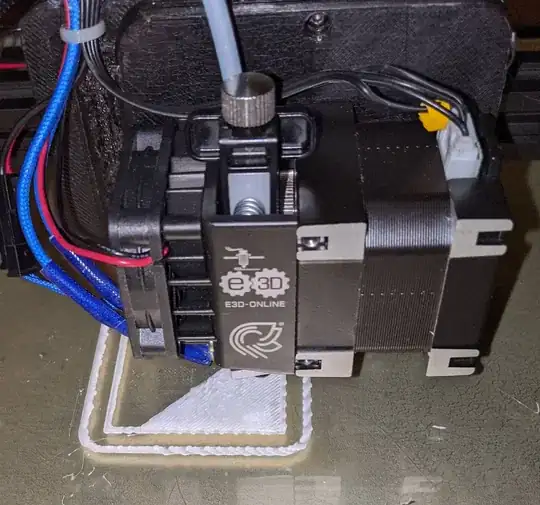

I tried printing a "improved" calibration cube and noticed that the printer was laying down dots instead of a solid line. This was right after switching out my extruder motor and tweaking retraction settings. I believe my first setting was 0.3 mm, then I tried 0.1 mm. I didn't get a picture of the first setting, but shown below is when retraction was set to 0.1 mm. I think the print was at layer 3 roughly. The difference is 0.1 mm had a higher frequency of dotting, ie more dots that were closer together.

This was only present in the first couple of layers. The dots weren't occurring in the same spot so the picture shows dots overlapping each other making a sort of "twisted" or braided look. This also happened on both the x-axis movements and the right side of the y-axis movements. The rest of the cube came out relatively well.

Settings

- Printer: Creality CR-10S

- Temp: 205 °C at nozzle; 60 °C on bed

- Retraction: 0.3 mm initially, 0.1 mm (pictured)

- Bed Distance: ~0.1 mm

- Nozzle Diameter: 0.4 mm

- Layer Height: 0.2 mm. I usually do 0.4, but I was lazy with slicer presets (AstroPrint)

- Hotend: e3D Hemera direct, e3D v6 heater and nozzle

- Filament: Hatchbox PLA white

I never saw this issue before on my printer nor have I seen it mentioned in various articles/videos online.