I got an Anycubic Predator last month, and after resolving a few mechanical problems, I was able to get it printing decently well. The only significant modification I've made so far is a set of 8-diode TL Smoothers, and I'm now mostly operating it via Octoprint.

However, during the last few prints, I've noticed the temperature dropping midway through the print. It warms up and cools down fine, but for some reason it's not able to sustain the temperature throughout the print.

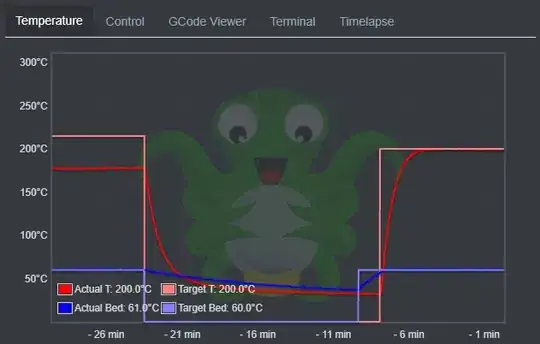

In this case, the print started out at the correct temperature (200 °C), held that temp for around 2 hours, then it dropped to a lower temp (174 °C). It eventually went back up to the target temp, then dropped again 5 minutes later. I tried manually adjusting it to see if that could fix it, but no luck.

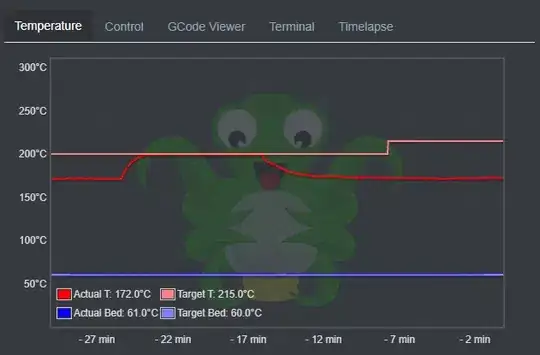

After this print completed, I restarted it to show how it is easily able to reach the target temp and hold it at the start of the print:

Any tips on diagnosing and resolving this issue?