What could cause that?

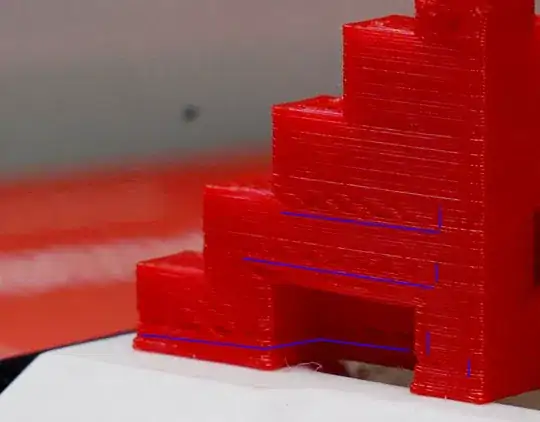

When linear_advance (v1.5) is "off" (M900 K0) - everything is uniform and smooth, only corners are protruding as expected.

When it is "on", I get these horizontal defects. My calibrated K-value is 2, I am getting same defects with K=1 as well as K=2. Position of defects is repeatable, so it is not random mechanics-caused underextrusion.

My setup uses a BMG Bowden extruder, A4988 drivers for Z and extruder with diode smoothers (X, Y are on TMC2209). I print the PETG with 245 °C, Perimeters at 50 mm/s, Gyroid Infill at 120 mm/s.

After the original posting of the question I tried the following:

Removed diode smoothers on extruder and Z - no improvement.

It seems defect is somewhat connected to infill. Without infill print is nearly perfect. 50x50 box without infill prints perfectly, so it does not look like outer-wall speed-related. Reduced outer wall to 33 mm/s, infill to 100 mm/s (accelerations are also down 750->500, 1000->750), no improvement. Returned to A4988 on all axis - no improvement. Switched to 1/8 step on extruder (maybe it is step speed-related) - no improvement. Disabled infill before walls - no improvement.

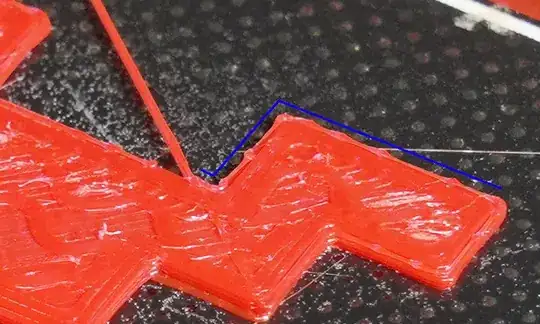

Starting shooting time-lapses, and outer perimeter is extremely weird on some layers (see below)

Migrated configuration to latest Marlin 2.0. Enabled SQUARE_WAVE_STEPPING - no improvement. Gcode is uploaded here: https://s.14.by/3d_issue.gcode

After inspecting larger parts printed before linear_advance (on large 100 mm circular parts) - I also noticed this defect, more rare though.

Connected to oversized lab power supply, to ensure there is no power sag during high load. 24V 16A max power consumption. Print defects remain exactly the same though.