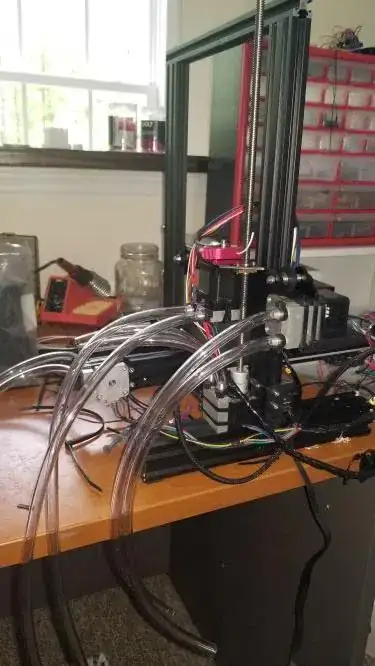

On a budget, I'm water-cooling a 3D printer. I'm using a 5 V aquarium pump (\$3). Originally I tried to only use about as much water in a can of chickpeas but then found out i needed a lot more. I have a deliberate need to water cool stepper motors in the first printer, so that I can print with a high temperature filament like PEI (the operating temp of a stepper is maxed at about 53 degrees celsius; PEI requires an enclosure temperature of 80 °C), but on another printer I'm having some other issues with the motors that I think could be solved by better heat dissipation.

What I am getting to is a device like this:

It is the perfect size for a stepper motor. My plan is to zip-tie one of these to each stepper motor and water cool it in a single path across my printer, including the hot end.

Can anyone think of a reason why this wouldn't work? i just haven't heard of anyone doing anything like this, but it makes sense to me as a chemistry minor. The specific heat of water is way higher than almost anything else. And it is way less noisy than fans. And it works inside an enclosure, while fans might not

Should I ziptie the aluminum block to the back part of the stepper where the metal is, or to one of the darker black sides?

Would I be able to 3D print a cooling block like this instead of paying for it? See also this relevant question on thermal conductivity of various 3D printing filaments. It should probably be metal to transfer heat better?