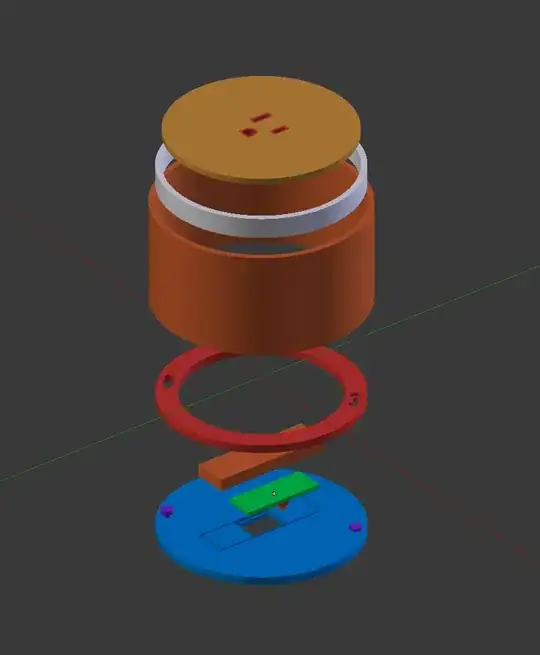

Here's the thing that I'm working on putting together (the purple stud on the bottom right should be up higher like the one on the left).

Notice how the purple studs fit into the red ring? Well, most of the parts are like that in one way or another. That is, most of the parts need to start right where another part ends with no gap and without being too tight.

Are there any good rules of thumb for knowing how much smaller a male part needs to be to fit into a female part? I want a good fit but I don't want to have to jam them in.

I'm doing this at the library and just getting down there and setup is an ordeal. The blue cylinder (4x102mm) alone takes almost 4 hours to print with a nozzle size of .6mm. ...I imagine this is how it must have felt when people had to program on punch cards, lol. Except, this isn't just a logic thing. It's an experimentation thing and it's taking up a ton of my time.

How can I get these parts to fit together perfectly like they do in my model?