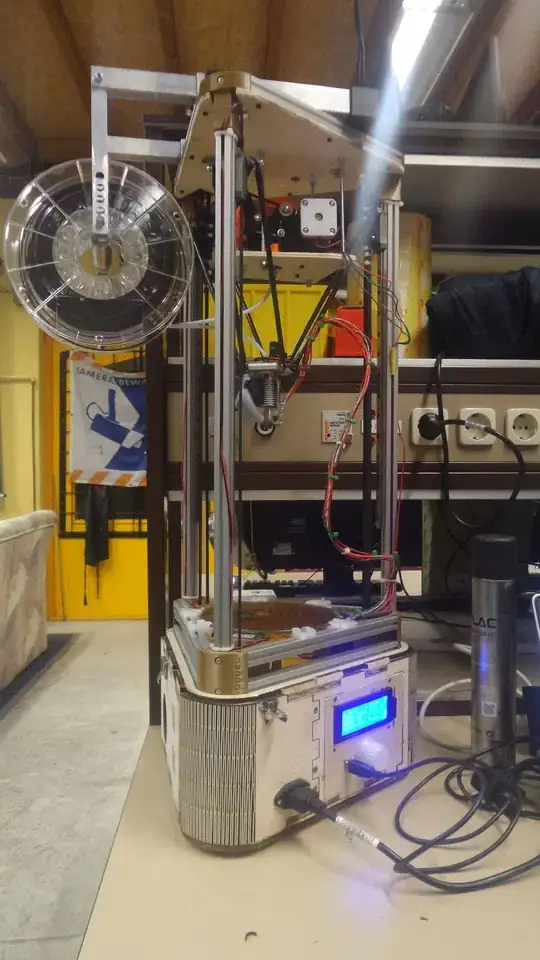

I want to build a 3D printer with a heating chamber of around 90 °C with build area 200x200x200 mm. I have never build a CoreXY system, so my design is currently an XY system with moving X motor (mounted on Y). Since it has a heating chamber I can't use normal stepper motor (there's a way, but I have to provide forced air cooling like NASA did, or water cooling). Extruder is Bowden type. I have already sourced almost all components, but I'm stuck at choosing the motor.

I could find high temperature stepper motor in India (that's where I'm from), but it cost too much. I found one at the Visionminer website, they're the dealers for Intamsys printers, which has a chamber of 90 °C and they are providing replacement stepper motors as well.

Comparing the cost, the motor I found in India costs three times as above. Even with shipping I will save a lot. But one issue is they're not providing any details about torque and current rating. There's one image in the website and it says,

MOONS STEPPING MOTOR

TYPE 17HDB001-11N

60904162 18/04/12

I thought it might be a MOONS motor, so I contacted them, no reply so far. I tried to find the motor by part number, but failed. I tried mailing Visionminer as well.

Anyone have any idea which motor is this or know any high temperature motors?

Also they use Gates belts, which is rated for 85 °C. How reliable will it be in 90 °C chamber?

I will heat the chamber using a external heater with fan.

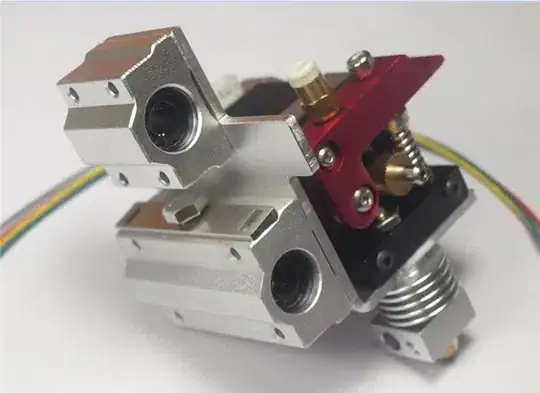

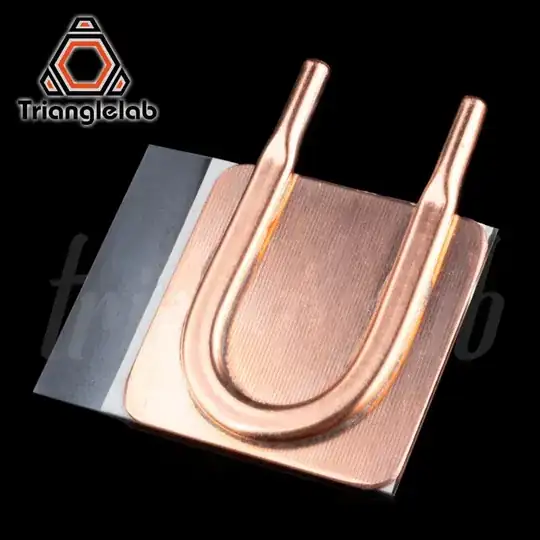

My extruder is Bowden, same as you've shown E3D V6, with updated high temp parts. Plated Cu heater block + Nozzle, High temp heating coil and Thermocouple.

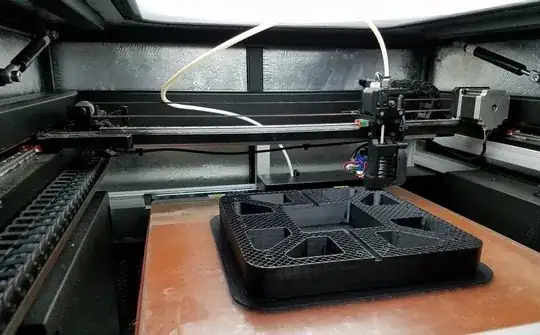

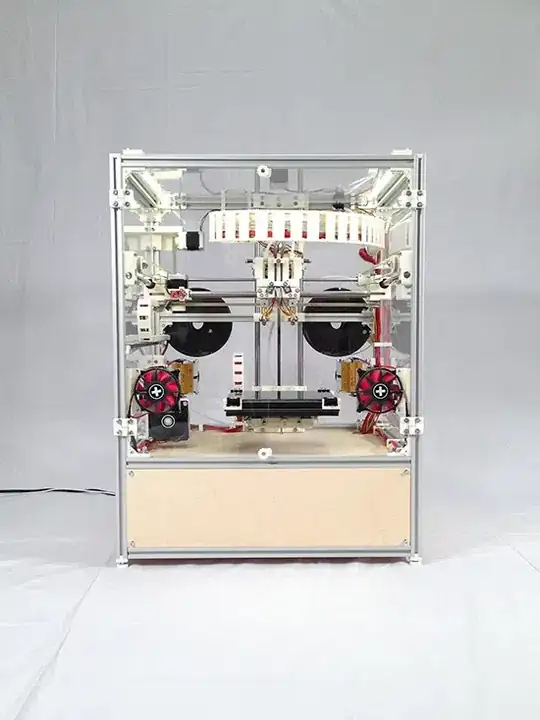

But In my design X axis motor is moving one. I mean it's mounted on Y Similar to this image

So it will be inside the chamber and I have to cool it somehow or looks for high temp motor

What I'm trying to print is PEEK, and it requires around 80-90 Degree chamber, and most stepper motors are rated for an ambient temperature of 50 Degrees. And I'm really planning to seal the chamber using SS sheet. It's going to be something like Intamsys funmat HT. What is the biggest print, I mean duration that you run your printer at 60 Degrees?