Has anyone made a cover for their 3D printer? Edit: What kind of Max temperature should be allowed? From the comments, I understand the control board and power supply should be outside the enclosure. I don't see a way to have the stepper motors outside. I do have a thermocouple probe and can monitor the temperature inside the enclosure; what can the motors be allowed to go up to?

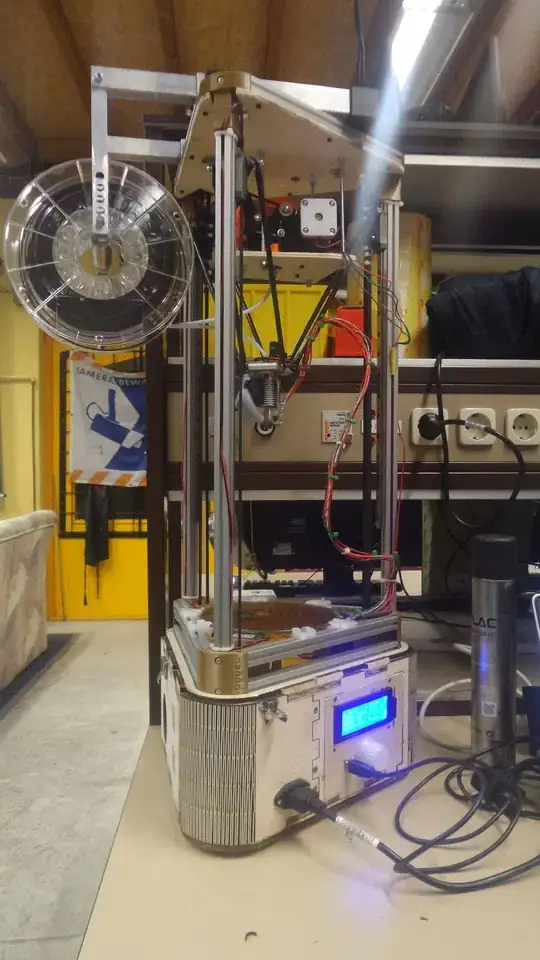

I have a Migbot i3 (prusa clone), looks like it will need a 24" x 24" x 16" cover (leaves room to put a spool on a holder inside also). I bought some 18" x 24" polycarbonate sheets to make a square box, but it's looking like it will be a bigger project than it was to get the printer running! I need to cut one down to 6" and join it length wise to get a full 24" for the top. And then print a bunch of corner blocks and drill holes for screws/nuts to secure it all together. Maybe make the front hinge up to lay on top to access the bed and the reel and the finished pieces.

I'm hoping the cover will block out some of the fan and motor movement noise, and as a side benefit keep cat fur & dust out of the mechanism, and perhaps even help keep the ambient temperature a little more even. I'm not sure that ambient temperature drifting makes much difference with PLA, but ABS is allegedly sensitive to that, and perhaps other materials as well.

Edit 5/25/19: Well, I went ahead built one, it's nearing completion. Found 18x24" Lexan polycarbonate sheets, and printed up corner brackets from thingiverse. Top back has a 6" wide space I can hinge up like the front cover to allow more airflow should things get too warm from the power supply or the 0.4mm nozzle. Have been printing PLA on a cold bed with Vertex PEI material clamped on it (waiting for WhamBam system with spring steel and PEX material, couple weeks out on delivery).

Will be securing it to a base so it doesn't get knocked off the folding work bench (again). Some wood added inside for some stiffness, the Lexan is kind of wobbly in big pieces like that. Looking at some magnets to replace the wing nuts/screws on the front cover, they're kind awkward to undo.

Taking off the Lexan protective film soon, might wait until securing to a base piece of wood is worked out. Think I have some thin OSB in the garage left over from another project.

Edit 5/26/19: Printed an hour+ component with doors closed and thermocouple hanging below the LCD screen. Minimal temp rise seen, just 3-4 degreeC, with ambient room temperature also rising some as the sun rose. Printing PLA on unheated bed.

Also changed door closure to have magnets hold closed door in place, works very nice. Wing nuts worked well, but screws stuck out and were hard to open once the screws went thru the door.

(not sure why these are rotated right 90 degrees, they looked fine when I cropped them on my PC)