I recently installed an original BLTouch V3 on my Ender 3 pro and ever since I can’t seem to get a decent print. My first layers are horrible.

The install wasn’t so bad, I really thought it would be plug and play thereafter.

I currently have:

- Version 1.1.4 board with non silent steppers

- Marlin 1.1.9 with bug fix as per the teaching tech video

- Printing on glass, bed @ 60 °C, extruder @ 200 °C

I have checked

- Bed is level.

- X gantry is squared/straight.

- Belts seem tight.

- Tried my best at getting the Z offset right.

- Checked E steps are correct.

- BLTouch seems to be working - not 100 % sure as it’s my first time using an auto level sensor.

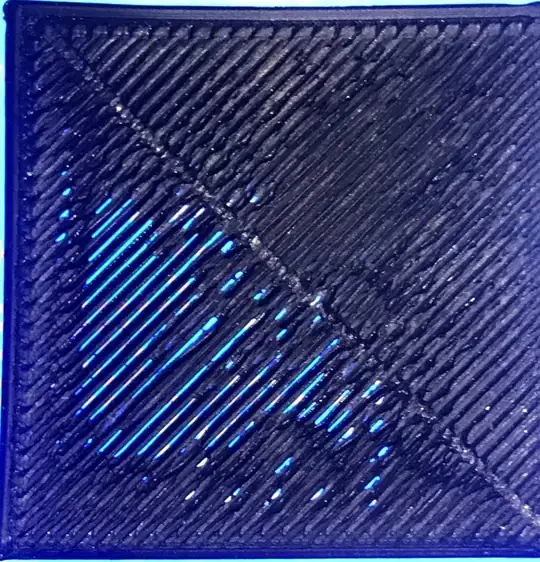

More pictures here for those who can help.

I have reset the offset and still having difficulty I’m hoping the following pics would help. They bed level squares that prints squares on all four corners and the centre of the bed plate. If I raise the offset any higher I have difficulty with prints sticking. See here.