The printer is "Monoprice MP Select Mini 3D Printer V2".

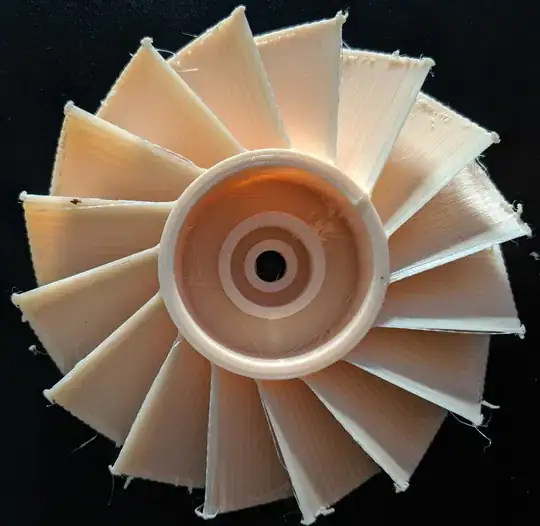

This is how my printed fan part looks like:

These printers are notorious for their Z lead screw assembly (M4 bolt & nut) so I installed flex coupler and aligned the M4 bolt and motor shaft so that the wobble is minimal. It is still there, but I don't think this amount of wobble would produce something like what I experience. Please check out the timelapse video at the end.

I also tightened up Z guide rails (no rattle, very little slop)

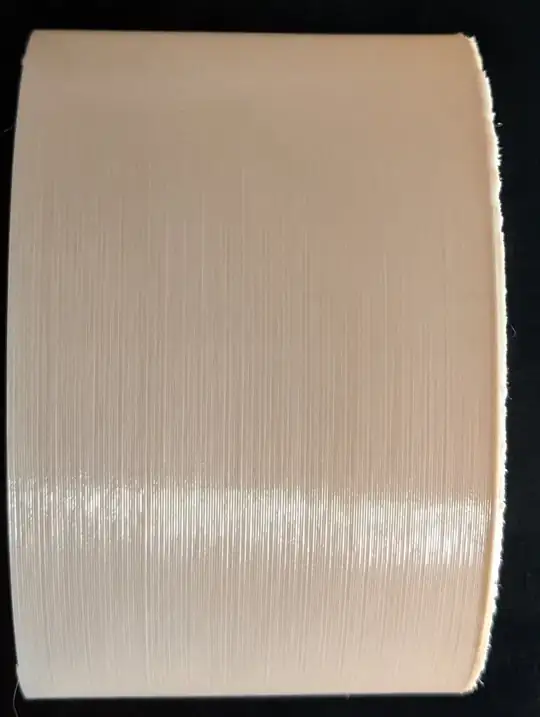

Moreover the banding appears to be less pronounced and have alot greater period for vase prints

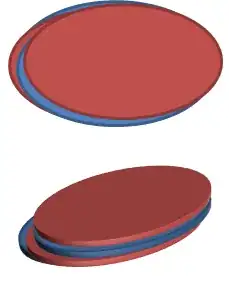

(this is extruded ellipse printed along Y axis). I tried:

slowing down print by 50 % - no effect on banding.

monitored hotend temperature with external probe on the heater block (-+5 °C)

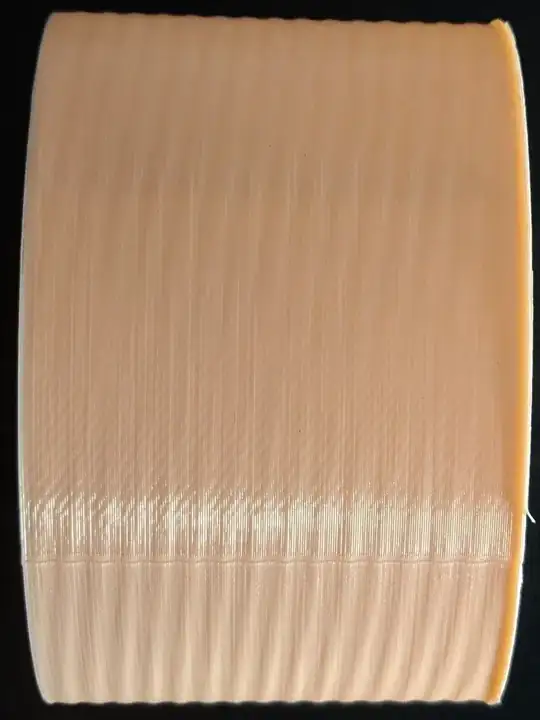

The banding appears to be almost exclusively in Y axis direction; for example, the same ellipse printed along X axis:

Now, same ellipse in layered mode (seam side) printed along Y axis