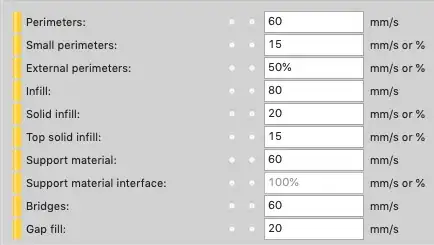

There are multiple parameters because of the trade-off at print speeds.

Slow printing will have less ghosting and a better overall quality, but it takes way more time.

Fast printing will be fast (oh thank you, Captain Obvious), but you will get stronger ghostings and poorer line quality overall. Maybe some strange artifacts.

But you don't need a good print quality in areas that are not visible at all, but you do need it for the outer shell. Also, is the travel mostly just something that you want done as fast as possible but maybe not so fast that that the whole printer starts shaking?

So, you want to set different parameters for different parts.

Next reason: most slicers are used for a large variation of printers, and every printer is a litte bit different—even the same printer type with different addons (like a vanilla Anet A8 vs. a beefed up Anet A8). For the slicer to be able to be used by all these printers, it is necessary to be able to set multiple parameters.

To get deeper into your question about the different infill speeds: if you print a solid infill you will also need to give the printed material more time to cool down, because it is packed tightly and there is not much surface area for heat to get away. If you print these areas too fast you will end up with a part that is too warm and warps and deforms all the time while the next layers were printed on already, inserting even more heat into the part and isolating the warm parts from the outside. You can observe similar behavior when printing overhanging areas with thick walls: there the part will stay in a semi-solid state, and deforms all the time.

But how fast you have to go depends on the cooling system you have on your printer.