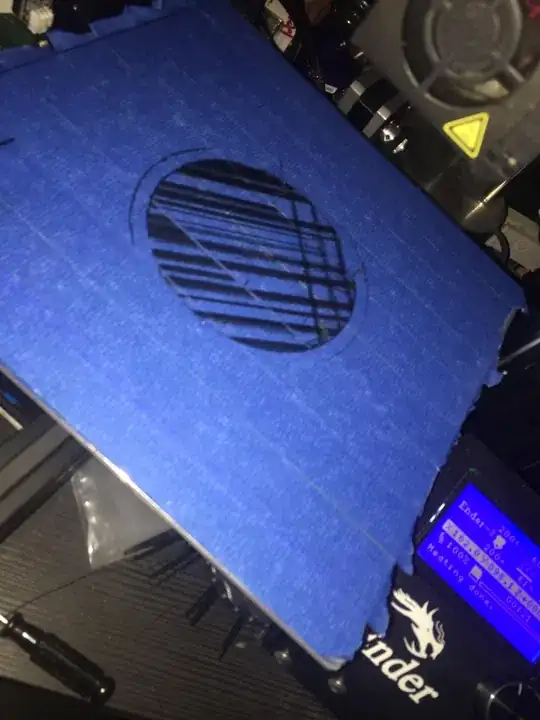

I have only been able to get my prints this far. They just can’t stop skipping pulling material up towards the nozzle which then melts pulls of another random bit. At first I thought it was motor skipping, so I strengthened the spring, but even after that and calibrating the bed, I couldn’t figure out exactly how to fix this issue. Hopefully someone has some idea what is wrong.