Print/material specific settings

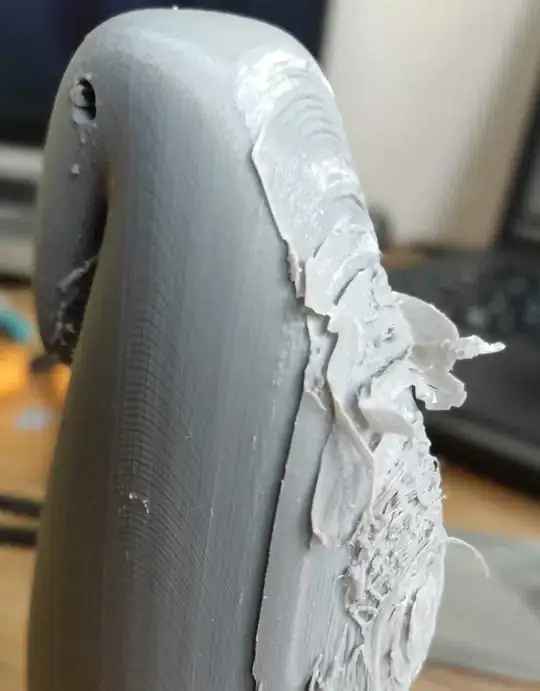

If you are printing too hot with too less distance, the support just fuses to the print object. Extra cooling, lower print temperature and support distance should be in balance to create easy to remove support structures with respect to an acceptable print object surface. If temperature and cooling cannot be balanced to prevent fused support structures (e.g. for high temperature filament materials that cannot take too much cooling as that would result in less structural solid prints), there is an option in Cura to override the fan speed for the first layer above the support (Fan Speed Override). If this fails to produce easy removable supports, you can resort to changing the support distance between the support and the print object.

Support settings

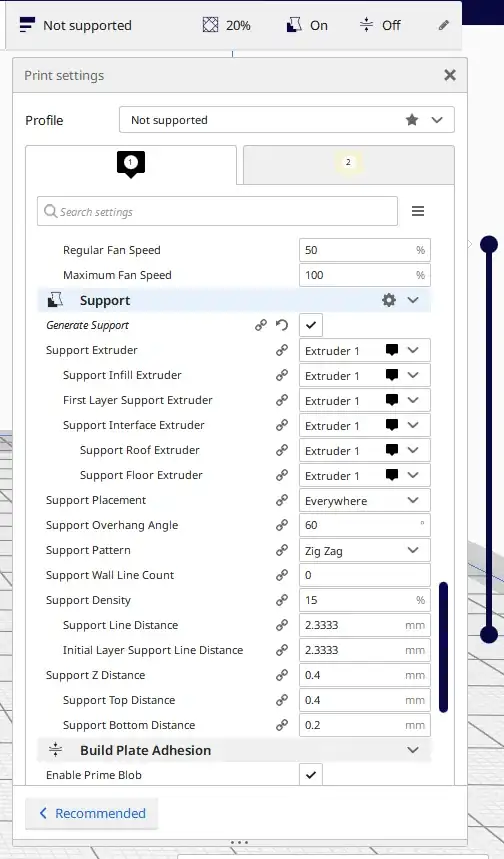

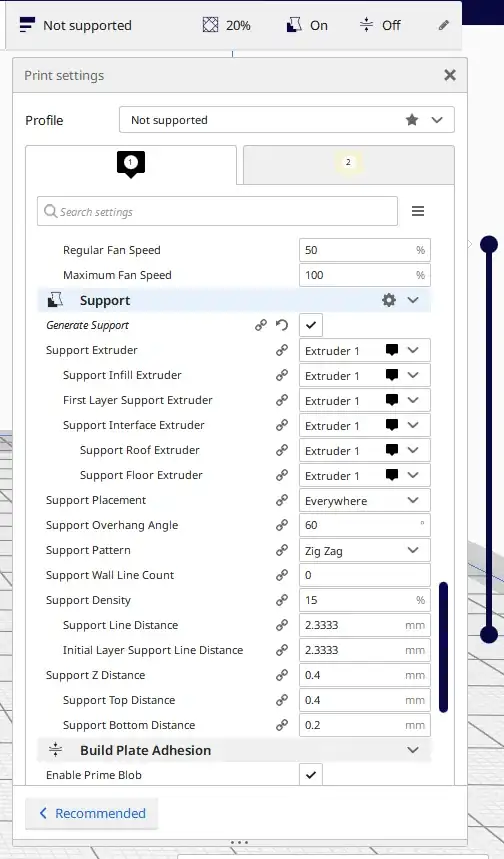

Most of the used slicers have an option to determine how much distance (in terms of layers) you want between your support and your product, you could add an extra layer as space to try out if that works better for you. E.g. the default Cura setting for Support Bottom Distance (which is a sub-setting of Support Z Distance) is the layer thickness specified in Layer Height. If you have a layer height of 0.2 mm, the Support Bottom Distance is also 0.2 mm. For the top, option Support Top Distance this is two layer heights, so 0.4 mm in this example. These options are visible in the expert mode, you can search for them in the search box, see image below.

Why should you want air in between your part and the support?

You'll soon find out when you want to remove supports, if no gap is used, the support will fuse to the print part. This is only interesting (no gap between print part and support structure) when you use a different filament for support like PVA or break-away filament; e.g. PVA dissolves in water in a dual nozzle printer setup (not that you can make the biggest part of the support except the top and bottom layer from the print object material, e.g. PLA for the main part of the support and PVA for the bottom and top layer: settings First Layer Support Extruder, Support Interface Extruder, Support Roof Extruder and Support Floor Extruder).