I am at the moment designing some in place mechanical parts. Something like two cylinders that rotate with respect to each other. I need in my design some overhangs that cannot be printed and I was thinking of using soluble supports to be able to print these overhangs. I am afraid that by using something like PVA the PVA will end up between the two parts and glue the together.

Does anyone have any experience with this? Can something be done about this apart from 'not using PVA'?

Edit:

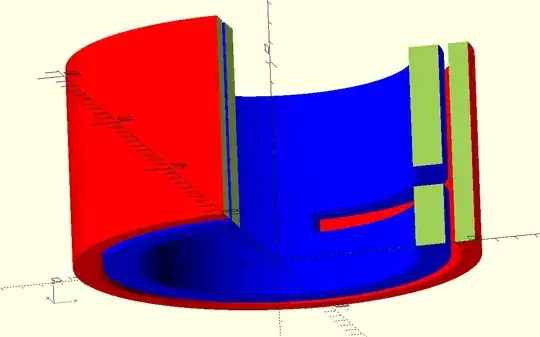

Here is an (minimal) example of an object I would be worried about. The blue and red cylinders are supposed to turn around each other and there is a cutout in the blue cylinder that will need support (the bridge is to long to print without support).