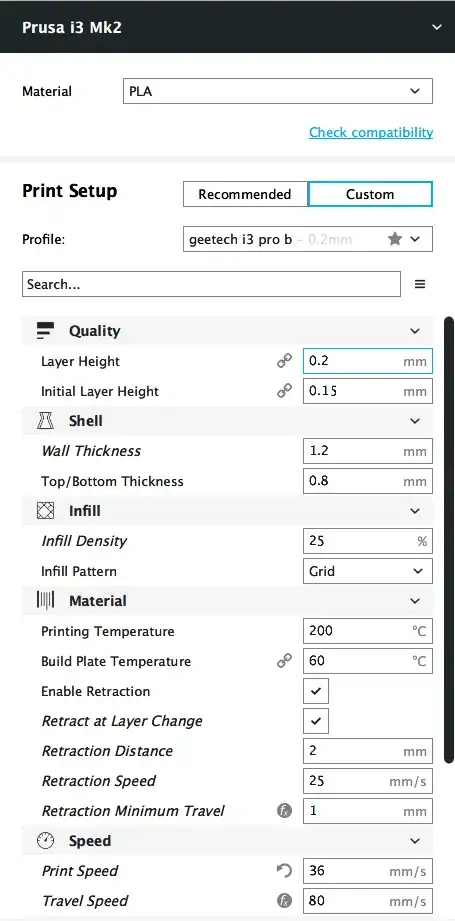

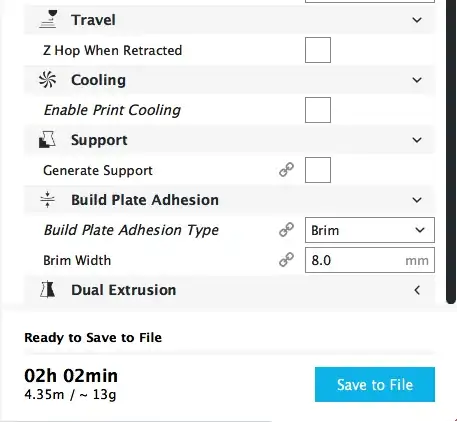

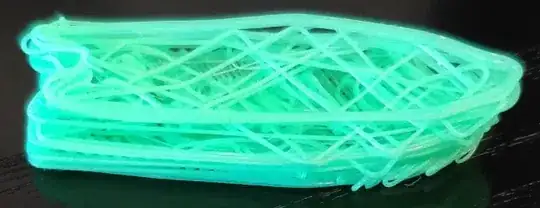

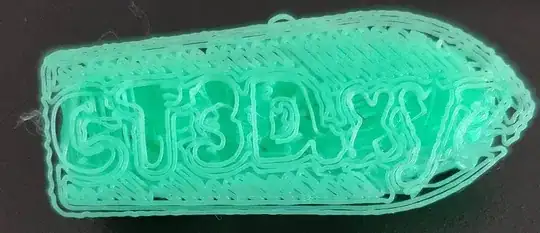

You need to level the bed properly by setting the correct distance between the nozzle and the bed. Ideally, you need to be able to drag a piece of plain A4 paper between the nozzle and the bed when the nozzle is at Z = 0 giving you a little drag (you feel that by a stuttering movement). From your pictures you can clearly see that the nozzle is way too far from the bed when depositing the first layer (as seen from the video you posted in the comments) as the hot filament drops/falls down to the hot plate. Once it is too far from the plate, each consecutive layer is too far from the previous layer.

From the images you posted, it is clearly visible that you have a mechanical/calibration issue. Your belts are probably not tight enough too, but it is difficult to say at the moment as the products are way off from what they should look like.

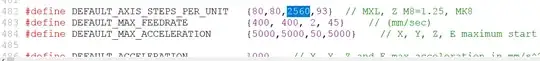

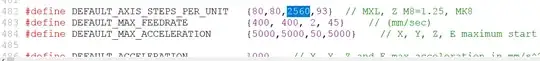

Note that the printer configuration could be incorrect (although very unlikely as it is out of the box). E.g. the stepper motor needs to make a certain amount of steps to advance the carriage in Z direction. If the mechanical layout requires 400 steps per mm (which is typical for TR8x8 (p2) lead screws on 1.8°(200 steps per revolution) stepper motors and 1/16 microstepping) but is configured as 800, your layer height advances twice as much although the Z=0 level would be okay! I now read (from the updated question) that the value for the steps/mm for the Z axis is 2560, this implies that you are using M8 lead screws with a pitch of 1.25 mm on a 1/16 microstepping board and 200 steps per revolution steppers.

From the specifications of your printer follows that the Geeetech Prusa i3 Pro B uses:

- Stepper Motors: 1.8° step angle with 1/16 micro-stepping

This image show the configuration of the axes:

So 2560 is correct!

Conclusion:

Your initial leveling and height setting is incorrect, when you printer is at Z=0, it actually is positioned higher. Hence your first layer has very bad adhesion and is not properly flattened and each consecutive layer shows the same problems of falling hot filament. When the speed increases on the next layers the hot filament deposition cannot follow the nozzle, hence the "spaghetti" looks.