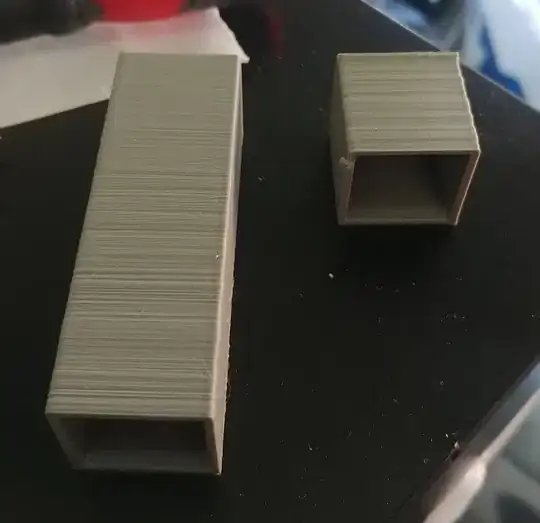

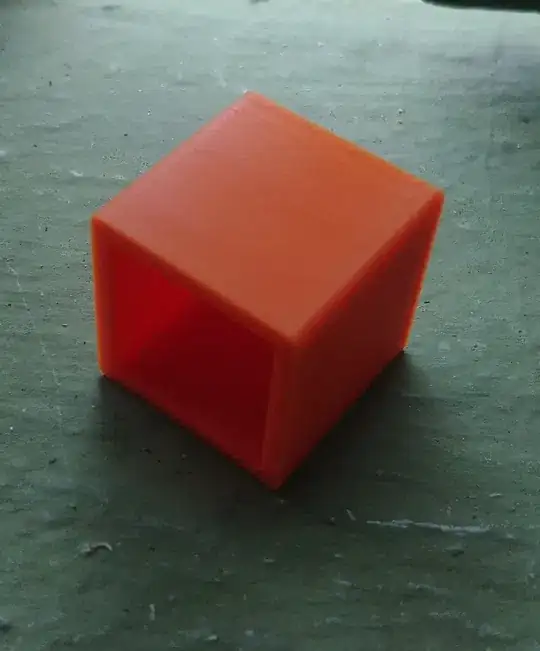

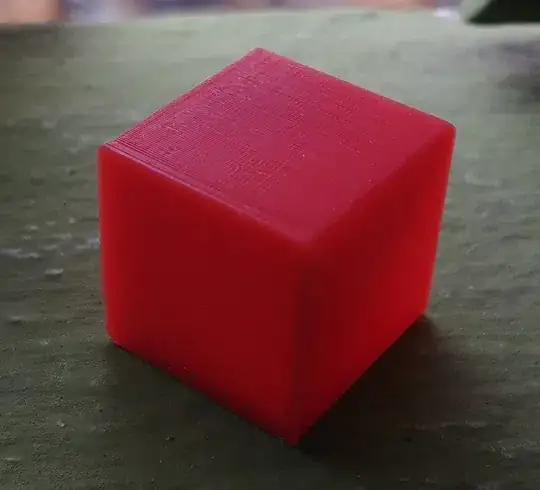

I'm 3D printing almost 2 years, and I expected to have better result after changing to complete smooth rods with new bearings.

I have a problem with my Z axis giving me inconsistent prints; I already replaced the leadscrews, E3D clone with Bowden tube, I decided to replace all smooth rods on all axis and also the bearings. After I replaced all this, my prints are still bad, also I'm very dissapointed with the results after the replacements. I have checked all I could think of; PID tuning, belts, ....) but I'm running out of ideas.

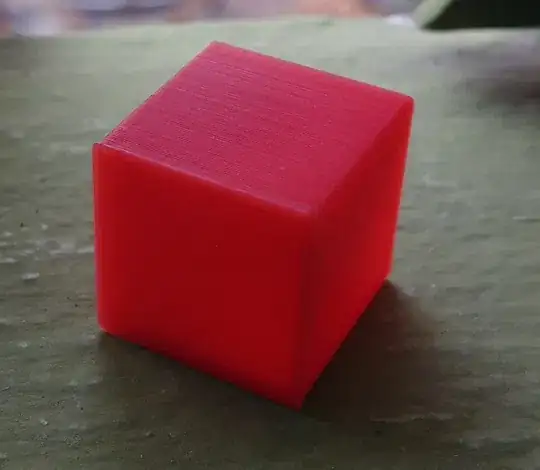

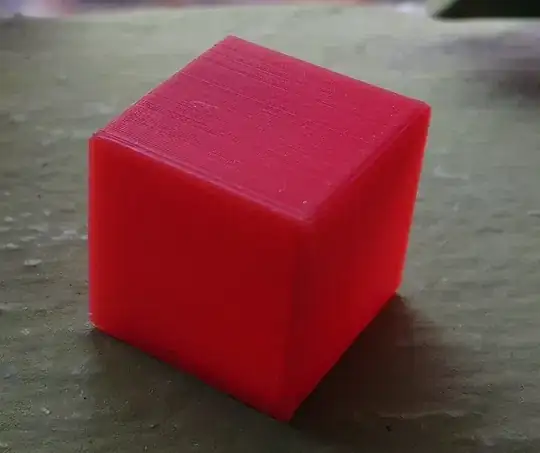

Printing settings:

- print speed is 40mm/s,

- retraction is 3mm at 30mm/s,

- extruder 205°C for the first layer, then 200°C