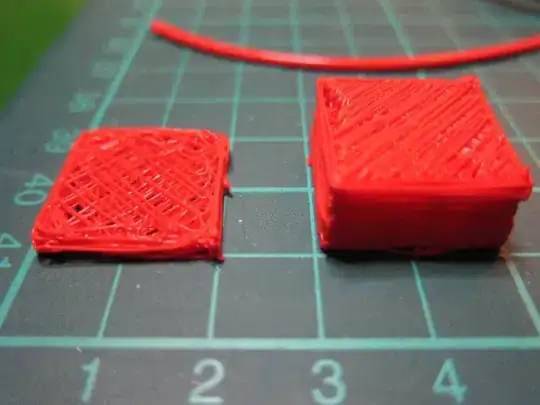

My Printrbot is always printing stringy, despite changing the setting on my z probe by entering command M212 Z-.1 through Z-1.5, with and without a heated bed. My prints look roughly like the one on the left. How do I fix this?

-

1What do you mean by stringy? Stringy as in underextrusion? Stringy as in strings between islands (problems with retraction)? Without pictures or a more detailed explanation, it's impossible to help. – Tom van der Zanden Mar 06 '16 at 20:12

-

Please elaborate on the conditions. What have your tried? You're question, in its current state is unclear or too broad. – tbm0115 Mar 07 '16 at 15:10

1 Answers

The most common cause of print issues like this is incorrect first-layer gap between the nozzle and bed. You can tell if that's the problem by trying to print with a raft and/or letting the print continue for a while. If the raft helps and the print eventually "heals up" and only the bottom few mm are bad, then you have a bed leveling / nozzle gap issue The bed must be leveled to the nozzle properly, or nothing will work right.

When using a probe, you need to follow the manufacturer's instructions for how to configure it. For example, are you adjusting the Z offset in firmware configuration.h or in EEPROM? Printrbot should have a guide for this.

If the nozzle gap is fine and the stringiness continues farther up the print, there are two main causes:

- XY or Z movement is larger than intended due to incorrect steps/mm value or wrong microstepping setting

- Severe under-extrusion

Of the two, under-extrusion is far more common, and unfortunately has lots of possible causes:

- Printing too cold for the material

- E-axis steps/mm is incorrect for the extruder drive hardware and microstepping

- Extruder stepper current is too low

- Extruder hardware is misaligned or jamming or the teeth are full of plastic dust

- Partial nozzle clog or damaged PTFE tube in the hot end

- Commanded flow rate through the nozzle is too high, such as if you're trying to print big, fat strands at high speeds

- Incorrect slicer calibration (eg extrusion multiplier is too low) or inappropriate slicer settings (eg extrusion width too large for the nozzle size)

- Excessive filament feed path drag between the spool and extruder drive

The first under-extrusion tests you should start with are:

- Preheat and try to push filament through the hot end by hand. Can you get a strand to come out without a ton of force? Does it go mostly down, or curl back up to hit the nozzle?

- Remove the hot end from the extruder drive, and command 100mm of filament motion through the extruder. Measure how much travel you actually get. It should be close to 100mm.

- With the hot end removed, command some filament motion, and try to stop the filament from moving by hand. Does it take some significant force to get the extruder to stall or slip?

Based on these, you should have a better idea of what needs to be fixed.

- 6,456

- 2

- 13

- 33