I've been printing successfully on my CR-10 for the past year now. I've had issues now and then but have been able to look around the internet and solve them. I've been using some Flashforge white PLA with great results.

Last week I got a couple of new rolls of filament, black and orange. SinceI tried printing with them, I've got nothing but jams. The white prints fine, however.

I dug around online and found this was happening to my printer: https://www.youtube.com/watch?v=-vH_spN5wyw

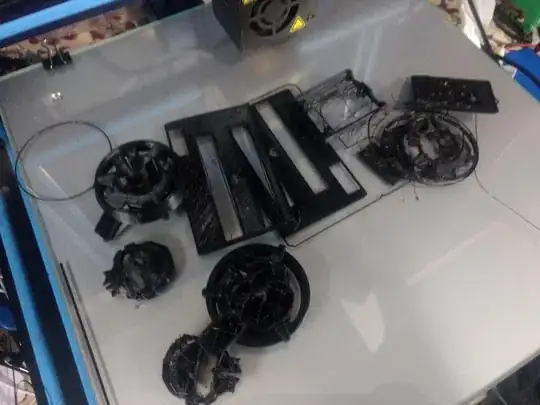

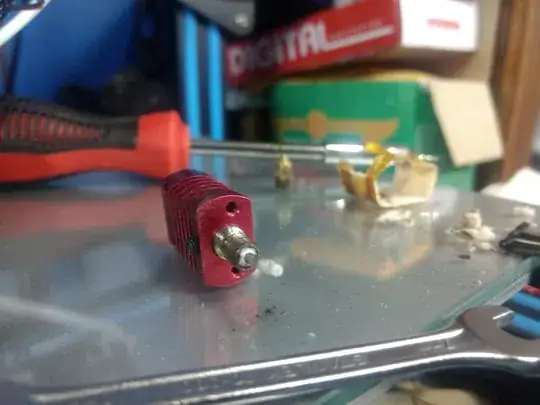

So yesterday I opened up my hotend to clean it out and got quite a bit of gunk out:

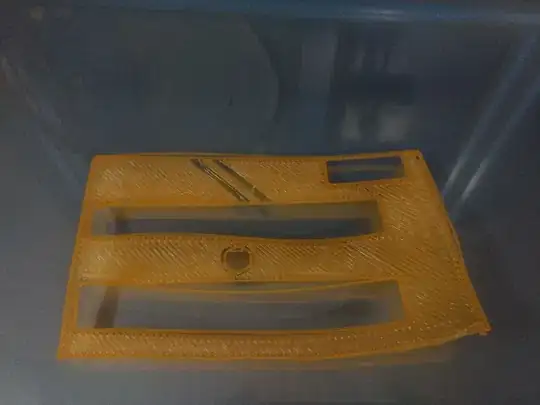

I also changed my nozzle. I printed some with the old white PLA and printed fine. The moment I switched over to the new orange filament, it jammed after a few layers.

I ensured my nozzle was tightened and then got to measuring the filament. The older white one is 1.75mm in most places with some at 1.73mm.

The new ones that I got are pretty inconsistent - the orange one ranging from 1.68mm to 1.72mm; I found very few places where it was actually 1.75mm. The black one averaged 1.72mm.

So I made the change in my slicer but even then the first layer was visibly underextruding and it jammed soon after. I took apart the hotend and cleaned it out. Now, I put the white one back and its back printing fine.

Should I go ahead and return the filament?