Problem: Z-Axis doesn't work during a print. It attempts to work, maybe climbs on the Z-Axis, but screws back down. It whines, too. But, Z-Axis DOES work while not printing. It doesn't matter if the bed and nozzle heating or not, if it's not printing, it works as it should. I don't know what else I can do to troubleshoot this problem.

I have:

- Changed the Ramps 1.4 board twice

- Swapped drivers around, bought new drivers

- Swapped X-Axis and Z-Axis motor connections

- Cleaned threaded rod.

- Leveled two Z-Axis threaded rod riders to near atomic perfection.

- Changed firmware to each of the 3 latest updates

- Remounted motor so both face same cardinal direction

- Cursed

- Changed jumper configurations from 16th microstepper to 8th for more power. No dice. Fried two drivers that way.

- Dialed and redial and tridialed and quaddialed the driver pots

- Recalled the Z-motors work while not printing so it isn't the driver pots

- Cursed again

- Scoured the web for similar issues

- Looked for G-code that might limit Z-Axis elevation

- Died a little. Just a little

Hardware:

- RepRap Guru DIY Prusa i3 V2 3D Printer Kit

- Ramps 1.4

- A4988 Driver

- Firmware:

- Marin 1.1.8,

- 1.1.7 (screen didn't function),

- 1.1.6 (screen didn't function),

- RepRapGuru_Marlin_v4,

- RepRapGuru_Marlin_v2

- Marin 1.1.8,

Additional information:

- My power supply is the original 12 V 360 W supply with the kit.

- The 5 amp power in is 12.02 V, the 11 amp power port is 11.96 V and 12.18 V depending on which heater is on.

- The bed measures 11.50 V and the hotend is 3.4 V

- While heating the bed and hotend I am using the LCD screen and rotary encoder to move my axes. It works as expected until printing. I have upgraded to an aluminum 12/24 V hotbed from the original PCB.

- Currently getting Repetier. Will update.

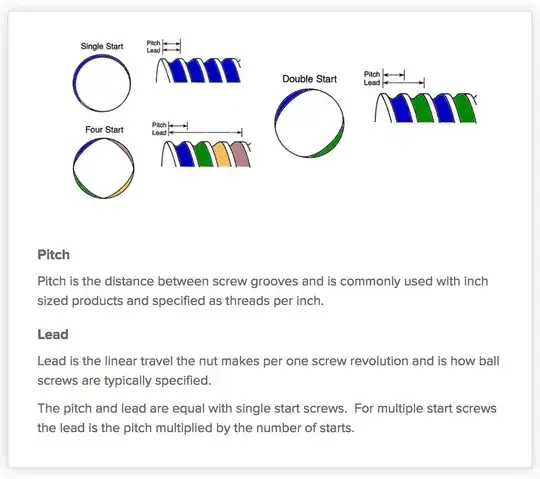

- The z-axis leadscrew is M5-0.8 mm