I would love to re-use my failed prints by re-extruding the plastic to be used in the 3D printer once again. One thing that stands in my way is finding an effective way to shred the plastic into smaller bits for the extrude to use. What is a good thing to look for to accomplish this? Maybe a really big 'paper' shredder?

-

2LMGTFY produces several pages selling shredders and tools which re-extrude filament. – Carl Witthoft May 14 '18 at 13:44

-

form what i've seen in youtube/forums it's not worth it. Making filament is hard because you have to nail the temp, extrusion pressure+speed, support the soft hot wet filament without drooping (which warps it) or sliding (which flattens it). Any variations in temp or speed will screw up the diameter. Any variations in scrap density will affect the temp and pressure. It's as complicated as nailing prints. Then you need to consider the effect that skin grease, dust, and other debris has on layer adhesion and uniformity. All in all it's not worth the time, equipment, or labor, at least not yet. – dandavis May 22 '18 at 05:48

-

1@dandavis You have a vary valid point, which is why I am still looking at doing this. I just watched some videos myself and it is indeed difficult from what I have seen. I just can't wait for something to come out that is simple to use and produces usable filament. I just hate not being able to re-use failed prints and knowing I could turn soda bottles into usually filament sounds great, but like you said its costly, time consuming, and difficult. – Ljk2000 May 24 '18 at 03:47

2 Answers

there is a project called precious plastic and there is a plastic shredder, but it is a rather expensive solution.

As I am waiting for parts for my Lyman extruder, my plan is to hammer the parts and then process in old kitchen robot with steel working area, an example here

The paper shredder will be ok as long as you can feed it with plastic.

- 1,922

- 1

- 6

- 24

-

I looked at the plastic shredder and darn it is rather pricey, but does look effective. I might do something similar to what your talking otherwise, for I don't make enough waste plastic to justify buying such a tool. But thank you for sharing that with me for it is a neat product. – Ljk2000 May 14 '18 at 14:12

-

I'm in the same boat as you, was contemplating spending $2000 on a shredder, and I was inspired by this RepRap article "Plastic Shredder using Kitchen Blender".

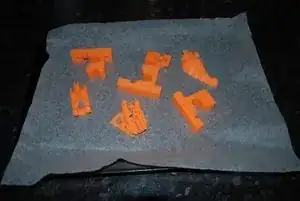

In which someone cleverly reminds us that thermoplastics melt. Put them on a baking tray on baking paper:

Melt them in the oven at a high temperature until they're pancakes:

The link puts them in a kitchen blender, but I've had success with a $70 micro-cut paper shredder from a local office supply store. The plastic puddles have a thin edge, which helps them fit into a shredder rated for "5 sheets of A4 at a time" (suggesting 0.3 mm max) but can process about 2 mm thick plastic if it gets a good lead-in.

The micro-cut particles it puts out are smaller than the PLA beads. I do mix recycled and virgin plastic together in varying ratios but mixing them evenly (especially with the dye beads) is tricky - it's very hard to get precise even colouring.

At 1.25 g/cc, 1 kg of PLA in an oven dish ~A4 sized is about 1.4 cm thick. So, aiming for about 100 g of plastic per dish will get you blobs averaging 1.4 mm. That fits through the shredder fine. 10 blobs make 1 kg of filament.

The only issue I have with the cheap office shredder is when you feed something slightly too thick in, occasionally the teeth deform the plastic into a chunk too big to fit into the shredder for a second pass, so that piece needs to go back into the melt queue.

-

Are there any issues with fumes from doing this? – RockPaperLz- Mask it or Casket Oct 30 '21 at 09:46

-

1@RockPaperLz-MaskitorCasket: PLA should not have any fumes issues whatsoever, but of course a lot of PLA is not actually PLA but some mystery blend. At least there are pigments (except in translucent natural color) but most "PLA" seems to contain at least some small part ABS or other acetone-soluble material, judging from what happens if you try putting acetone in a vessel made of printed "PLA"... – R.. GitHub STOP HELPING ICE Oct 30 '21 at 18:16

-

Have you checked the power cost? Might be interesting to see the cost of power for all this. – Criggie Oct 31 '21 at 20:25