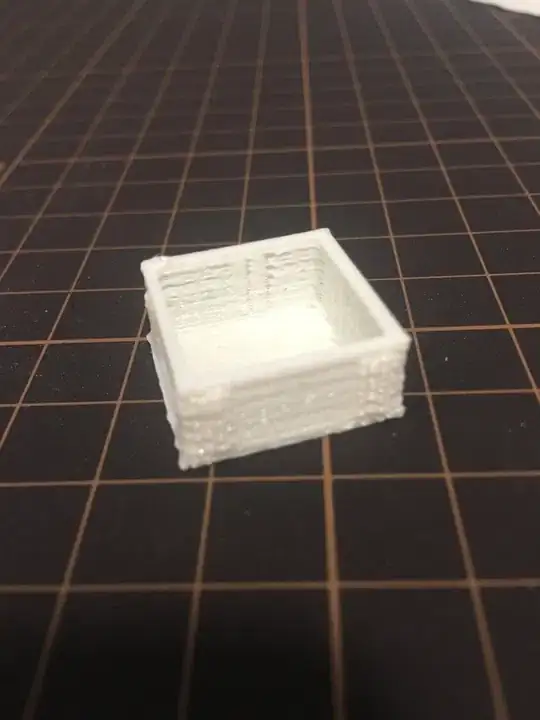

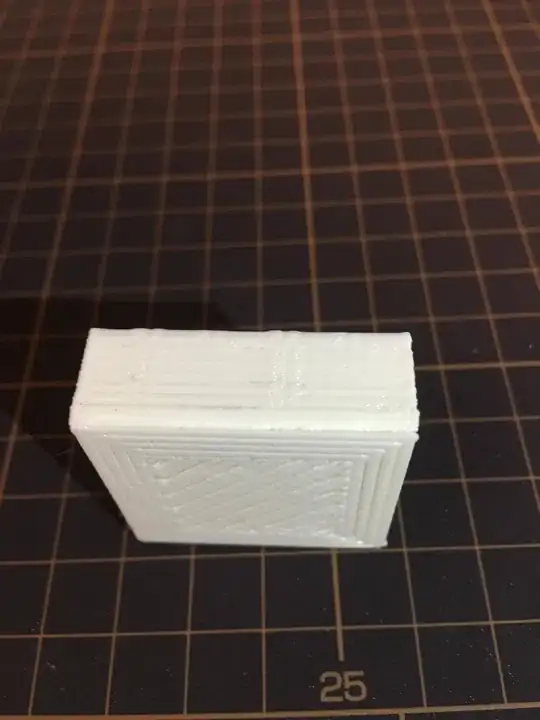

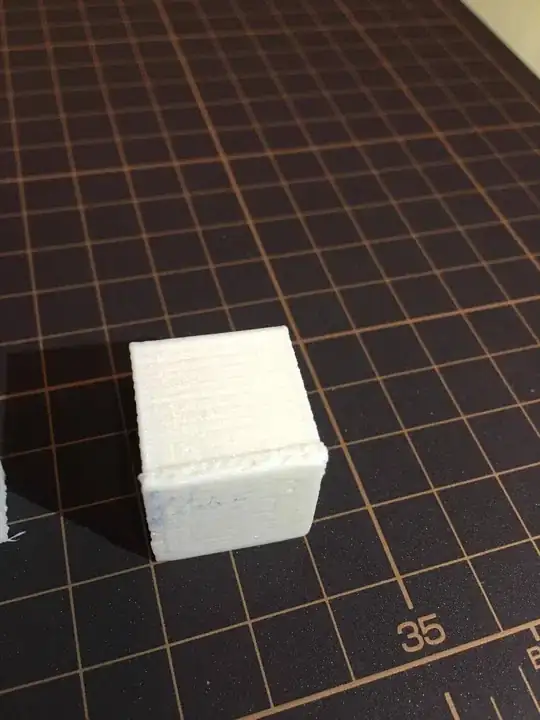

My model looks like this, does anyone know what's going wrong?

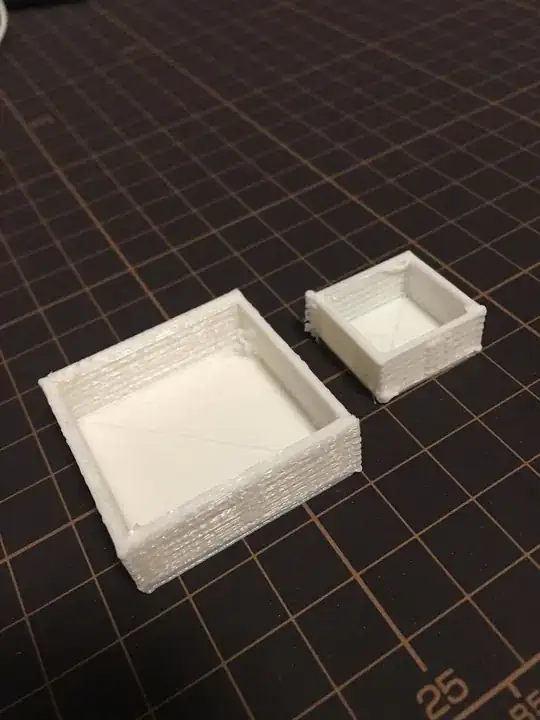

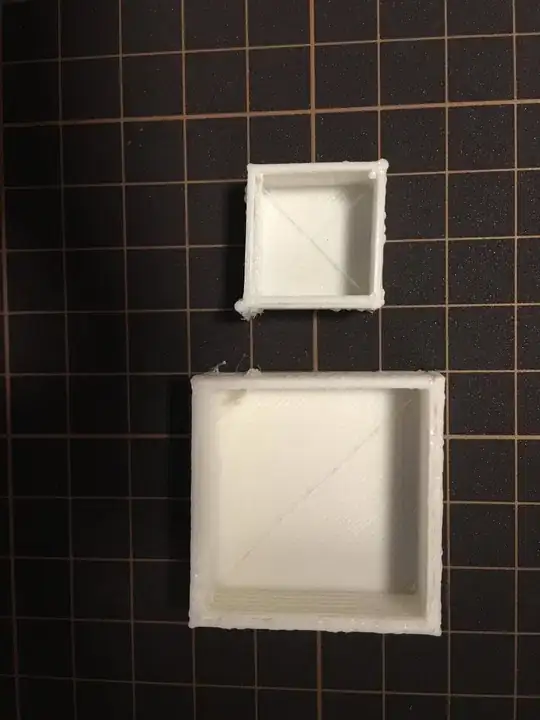

I'm thinking that if the small object looks like that, it's probably because of the slicer? And how about the bottom part of the cube... ummmm... I really don't know

I'm using an M3D printer, its own slicer and PLA at 205°C

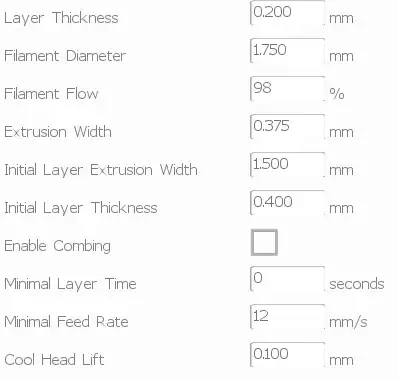

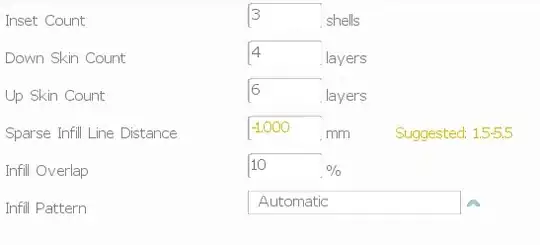

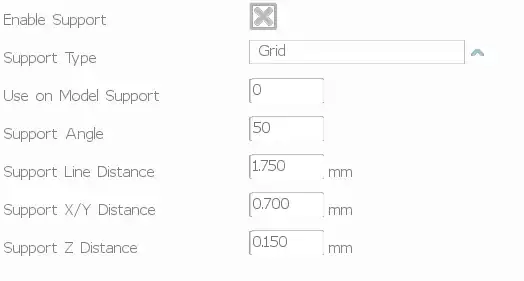

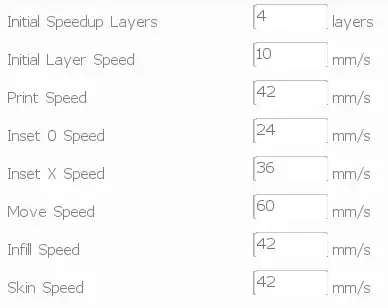

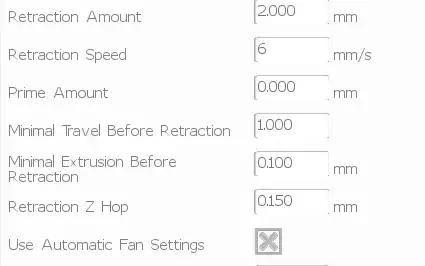

Settings:

- Layer thickness: 0.200 mm

- Extrusion width: 0.375 mm

- Filament flow: 100% -->98%

- Print speed: 30mm/s -->42 mm/s

- Retraction amount: 2 mm

- Retraction speed: 6 mm/s

- Minimal travel before retraction: 1 mm

- Retraction z-hop: 0.150 mm

Update:

The smaller object is using the same file but resized.

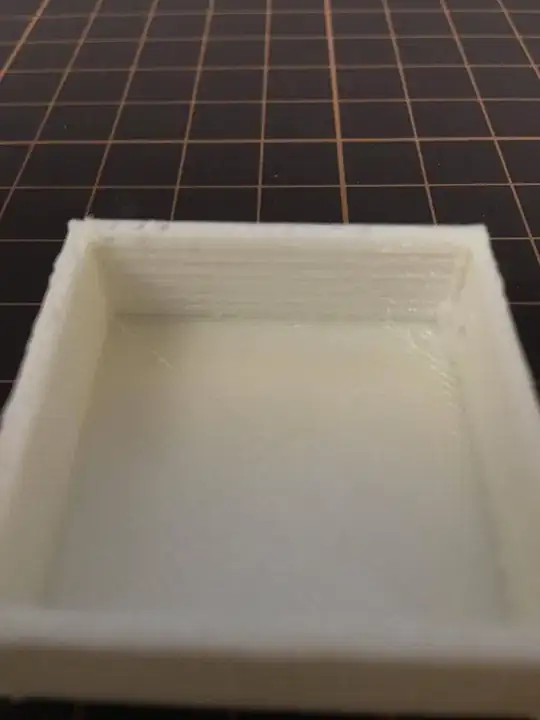

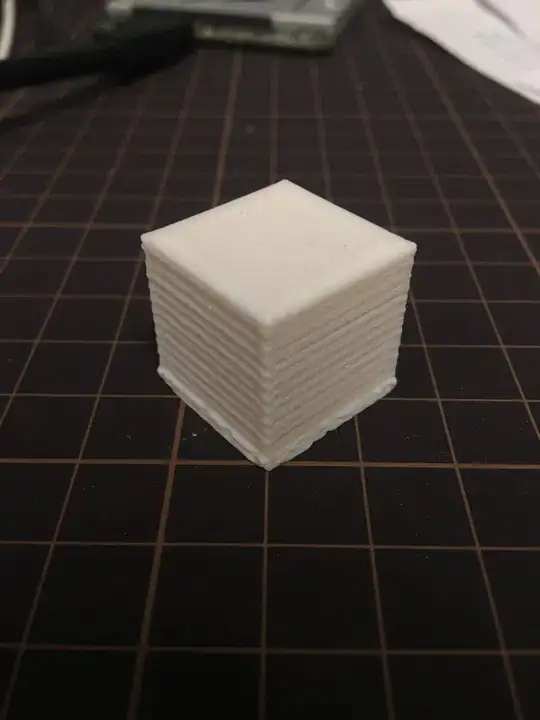

Here's the calibration cube. After I've changed the filament flow to 98%, it seems that the situation became better. But, it might also be the problem of the slicer as the two object isn't the same.

Update :

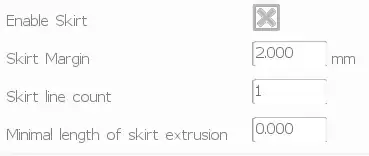

Here are the settings