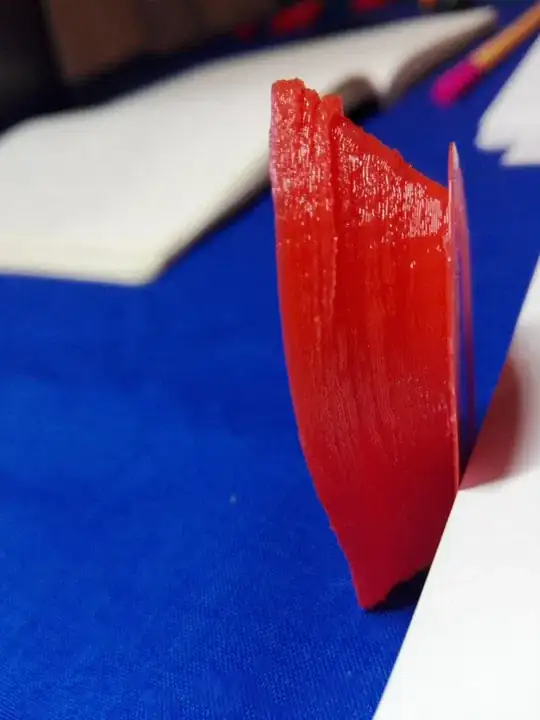

I am attempting to print the Benchy boat but every attempt so far has been unsuccessful. The print has a sort of slope/blob on the nose of the boat, which emerges after the first 30 layers.

Here you can see the front of the boat already arching up:

I have tried decreasing speed to 40 mm/s but the issue remains.

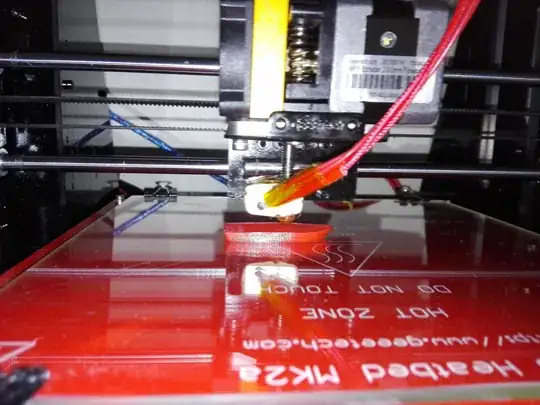

Printer: Geetech Prusa I3 Pro B

XY Accelleration: 1000 mm/s2

XY Jerk: 20 mm/s

Retraction Accelleration: 2000 mm/s2

Extruder Jerk: 5 mm/s

Printing Speed: 50 mm/s

Travel Speed: 120 mm/s

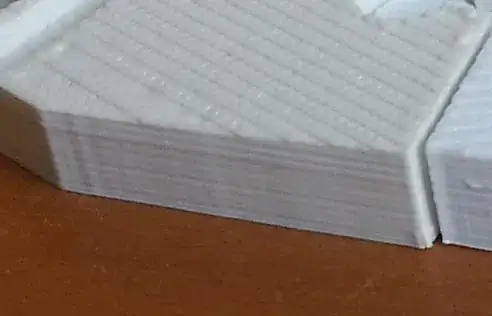

Layer Height: 0.1 mm

Infill: 60% (Lines)

Material: PLA, 200 °C, 1.75mm filament, retraction enabled.