One of the most interesting field in which the 3D Printing is being considered is the fabrication of biocompatible devices and parts for a medical applications.

For that I am interesting in knowing what technique are used for the fabrication of splints or cast used for the immobilization of human body part, also which material is compatible with this technique?

- 20,169

- 10

- 43

- 92

- 51

- 4

-

1I am pretty sure **any material and manufacturing process that needs to be used in a medical environment is subject to tight regulations that are possibly country specific**. Materials like lead - commonly found in FDM printers parts that come into contact with the filament - are potent neurotoxins, and exposure to some additives used in resins and plastic polymers is also considered a health hazard. So beware that even if the answer may turn out to be "FDM printing PLA", both the printer and the PLA may be specialised "medical grade" ones. – mac Feb 03 '18 at 04:23

-

@Mac please say more about "lead commonly found in FDM printer parts". This is news to me – OyaMist Jul 06 '18 at 15:22

-

3Lead is often used in metal alloys to alter their physical properties. For example, it is very common to find it in machined brass parts (a nozzle is precisely that) as it increase its machineability. Basically you should consider any metal part touching the filament (cog wheel, hot end, nozzle, ...) as a potential source of contamination unless you are positive of the contrary. – mac Jul 13 '18 at 06:20

-

2I'm voting to close this question as off-topic because it is a) too broad and b) a list question asking for 1) techniques 2) materials – Trish Dec 12 '18 at 09:42

-

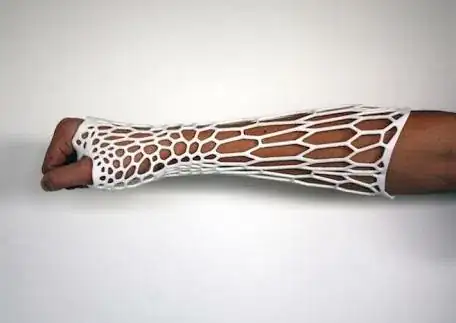

1The photo you posted is of a cast that was printed using Nylon and FDM, or the extrusion method. Source: https://www.evilldesign.com/cortex – Tyler S Feb 03 '19 at 21:41

-

@mac: Lead is not present in fdm printed parts in any appreciable amount. You can do the math with mass of nozzle, percentage of lead in brass, maximum loss assuming some ridiculous enlargement of orifice due to wear, etc. and affirm this. Stop with the ridiculous FUD. – R.. GitHub STOP HELPING ICE Aug 30 '19 at 01:08

-

@R.. - Your math may be right, but you are missing the general point: it's not that if you use a off-the shelf machine you will necessarily die or get sick. It is rather that medical equipment gets tested and certified so that you can be sure you won't. Lead contamination is most definitively one thing it is commonly looked at. Lead soldering is for example forbidden in medical equipment, even if patients don't get in direct contact with the electronics. – mac Sep 16 '19 at 09:57

1 Answers

For anything where there is an open or bandaged wound, you should NOT use 3D printing, and should use sterilized medical equipment to prevent infection and heavy metals infiltrating the bloodstream.

SLA/SLS 3D printing may be the best option for replicating the complex structure of the splint you have pictured above, as FDM printers have difficulty reproducing those structures.

However, FDM printing CAN reproduce it, and generally FDM printers have access to a wider variety of materials of which models can be printed with, so they may be the best option overall.

For something to immobilize a body part that has been broken, you may want to use a stiff material such as ABS or Carbon Fibre, However PLA may work still in these cases.

As for something to support a body part, Flexible or Semi-Flexible materials may be desired, such as Ninjaflex (TPU), Nylon.

As a disclaimer:

I am not a medical professional, This is not medical advice, please consult a properly licenced medical professional first before using 3D printing to solve a medical ailment.

- 677

- 4

- 19

-

PLA is very stiff, moreso than ABS I believe. That means it's also more brittle though. – R.. GitHub STOP HELPING ICE Aug 30 '19 at 01:10

-

note that you could arguably print the splint flat, then heat it some in an oven and wrap it around the bandage, creating a perfect form fit. – Trish Aug 30 '19 at 08:22

-