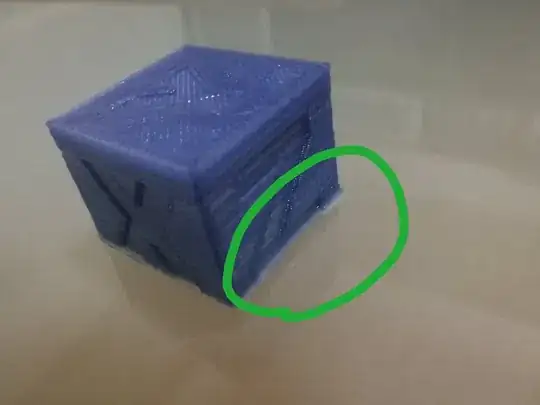

I tried to print 30mm calibration cube with my TEVO Tarantula. I found that a few bottom layers was missing as shown in picture. I noticed that a few bottom layers looks thin during printing. Anyone know how can I solve this ?

-

Most probably a problem of the model being sliced with its base at a height below the printing bed. What slicer are you using? – mac Jan 27 '18 at 14:42

-

I 'm using Slic3r. – 3ORZ Jan 27 '18 at 15:33

-

@3ORZ Seems like your nozzle is lower than Z0, probably Z -0.5 with this you will miss a couple may be 3 layers. Is needed to adjust the Z offset. – Fernando Baltazar Jan 28 '18 at 00:16

-

I set Z offset 0 How can I know what value I should set ? – 3ORZ Jan 28 '18 at 05:05

1 Answers

Anyone know how can I solve this ?

In order to know how to fix it, you must first diagnose what the problem is.

Two things you should verify in Slic3r:

- Check that under "printer settings" the Z offset is really what you want it to be (if you don't know what that is, you want it at zero).

- Check that in the preview (Plater plane, the "preview" tab is on the bottom), you can actually see the bottom layers being generated by the slicer (you can verify this by moving up and down the slider on the right of the main window).

If both of these checks are positive, then the problem is probably not with the slicer but with the printer or printer setup. The ultimate proof of this would be to try another slicer like for example cura.

If the problem is with the printer, the only obvious one I can think of, is that the bed is too high, the nozzle touches is, and the plastic cannot be extruded for the first few layers.

You can confirm or refuse this hypothesis by simply observing the printer while in operation. If it is the case:

- you should observe the nozzle moving "as if" it was extruding the first layers

- the nozzle should be touching the bed

- very little plastic should remain onto the bed

- you should hear some grinding or clicking noise from the stepper motor of the extruder (as the printer will try to push the filament, but the filament will have nowhere to go)

If you realise this is the problem, stop the print immediately: this is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat complex and tedious procedure.

The good news is that if this is the problem, the solution is trivial: you should simply set the nozzle height correctly. How to do this changes from printer to printer and you should refer to the user manual of your printer. Here is a video showing a few of the most common method to achieve that.

- 4,557

- 1

- 12

- 35

-

Oh, obviously !! Few bottom layers I hear clicking noise and very little plastic remains as you said. I will try to adjust limit switch of Z axis right now !! – 3ORZ Jan 28 '18 at 04:20

-

The bottom layers appear !! But still missing 2 mm on Z axis. Can I adjust Z offset to fix this missing ? – 3ORZ Jan 28 '18 at 07:50

-

@3ORZ - you can use Z offset (that's the reason that setting exists in the first place!). It is normally consider best practice to tune the hardware instead though, as otherwise you will have to remember to to set the Z-axis on every slicer you will ever use. The offset is normally there as a last resort, or for when you use multiple beds with different heights. But the effect is the same: so there is no technical disadvantage in using it. :) – mac Jan 28 '18 at 08:34