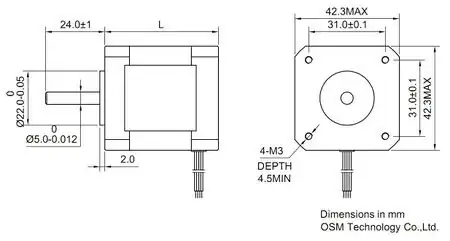

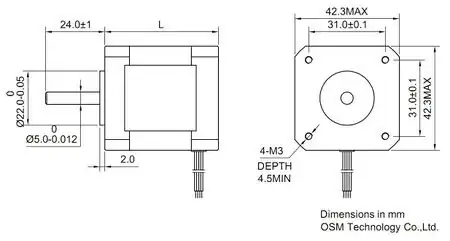

If you can access the stepper motors within the printers, then you should be able to obtain some basic measurements of its dimensions, in particular, the mounting holes. Then compare it with the dimensions of a NEMA 17 stepper motor:

Image from RepRapWiki - NEMA 17 Stepper Motor

The dimensions of other stepper motors, NEMA 11/14/17/23, can be found here: RepRapWiki - Nema Motor. The emphasis is mine:

Some (all?) NEMA 11 motors (is this specified in the standard?) have blind mounting holes about 4.5 mm deep, tapped to accept

M2.5x0.45 metric bolts. The 4 mounting holes are in a square 23 mm

(0.905 inch) center-to-center.

Some (all?) NEMA 14 motors (is this specified in the standard?) have blind mounting holes about ???? mm deep, tapped to accept M4

metric bolts. The 4 mounting holes are in a square 26 mm (1.024

inch) center-to-center.

Some (all?) NEMA 17 motors (is this specified in the standard?) have blind mounting holes 4.5 mm deep, tapped to accept M3x.50 metric

bolts. The 4 mounting holes are in a square 31.0 mm (1.220 inch,

about 7/32) center-to-center. The holes in the part that needs to be

bolted to the NEMA 17 motor typically need to be reamed out with a

1/8" drill bit to allow the M3 bolt to pass through. The drive shaft

is typically 5 mm dia.

Some (all?) NEMA 23 motors (is this specified in the standard?) have through mounting holes, a smooth 5 mm (0.2 inch) diameter. The

4 mounting holes are in a square 47.1 mm (1.856 inch, about 1+7/8

inch) center-to-center. The drive shaft is typically 1/4 inch (6.35

mm) dia.

However, knowing whether the stepper is a NEMA 17 or not may not be sufficient as there are very many variations of the NEMA 17, w.r.t. manufacturer and model. Again, please refer to RepRapWiki - NEMA 17 Stepper Motor to see a list of some of the NEMA 17 steppers available, and in common use in 3D printing.

The characteristics (Torque, Steps per revolution, Inductance Resistance, Voltage, Rated Current, etc.) vary greatly between models (even with the same NEMA type - 11/14/17/23), and some are more suited for particular applications than others.

With respect to your comment, why is NEMA 17 most common? Well, NEMA 23 steppers were used in some of the early [desktop-sized] printers, but then it was found that NEMA 17 steppers, which are smaller (leading to more compact, slightly less power hungry and lighter designs), offered less vibration whilst still providing sufficient torque. Smaller steppers (NEMA 14) can be used, but probably lack the torque to power a standard sized printer and can be only really used with very light-weight small printers.

NEMA 23 steppers are still used in larger [industrial] scale printer designs.

Again, from RepRapWiki - Nema Motor

The first working RepRap used NEMA 23 Stepper motors for positioning and a different kind of motor for the extruder. As of 2013, most RepRap designs call for NEMA 17 Stepper motors or NEMA 14 Stepper motors for both positioning and extruding.