I am re-writing this question because, well, it needs to be updated.

I have the Anet A6, but in a general sense of things, what kind of threads can I produce before it no longer works?

I am re-writing this question because, well, it needs to be updated.

I have the Anet A6, but in a general sense of things, what kind of threads can I produce before it no longer works?

This depends on the nozzle diameter, the layer thickness, and the material.

I've made very good M8 and acceptable M6 threads (nut and bolt) at 0.2mm layers with a 0.5mm nozzle, out of ABS, and also out of PETG.

I don't have a printer like yours but it should not matter.

Once you follow the calibration steps listed at https://github.com/AndrewEllis93/Print-Tuning-Guide/blob/main/articles/extrusion_multiplier.md and you set the slicer to 0.1 mm, you should be able to print working threads at the first attempt.

I printed in PLA a thread (both screw and nut) with a 1.5 mm pitch and it worked immediately (it was a bit hard to turn, it got better after using it few times).

A G 1/2 thread (pipe thread) in ASA (only nut) also worked immediately.

I had more issues with deep threads: M30x1.5 worked immediately, but I couldn't get M30x3 mm to work. Basically printing threads with pitch from 0.8 to 1.5 mm should be fine if the axis is vertical.

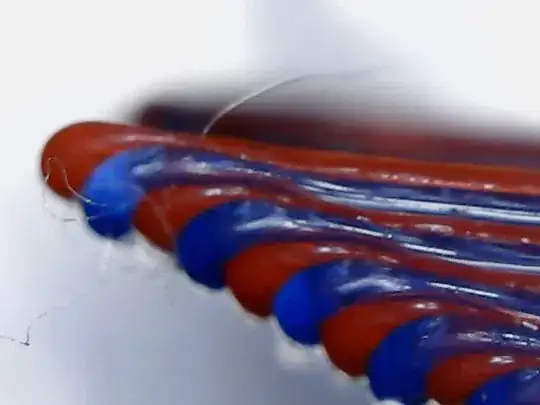

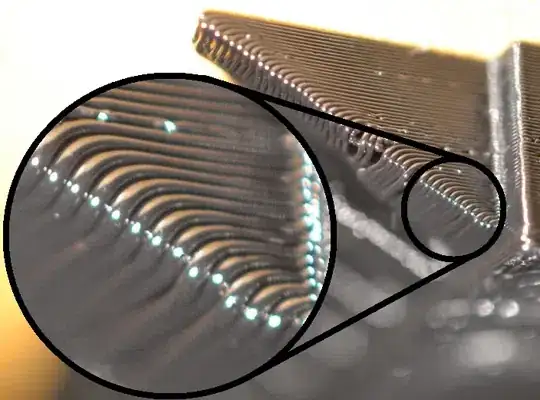

0.1 mm layer height is important to keep overhangs small, see video

The nozzle is not so important, you can use 0.4-0.6 without issues. I used 0.4 mm.

I have found that I get slightly different results with different printers and different plastics and print temperatures. For doing parts like nuts and bolts you will probably have to print several prototype parts once you get your printer to get the setting and tolerances right, once you get a print. But just decreasing the layer height and getting the nozzle temp and cooling right should let you get some working parts.

You can get the sloped surfaces the still look ok but are not dimensional accurate with to high an angle. I find if is easiest to print and then test and then adjust the tolerances on the design.

You can get the sloped surfaces the still look ok but are not dimensional accurate with to high an angle. I find if is easiest to print and then test and then adjust the tolerances on the design.