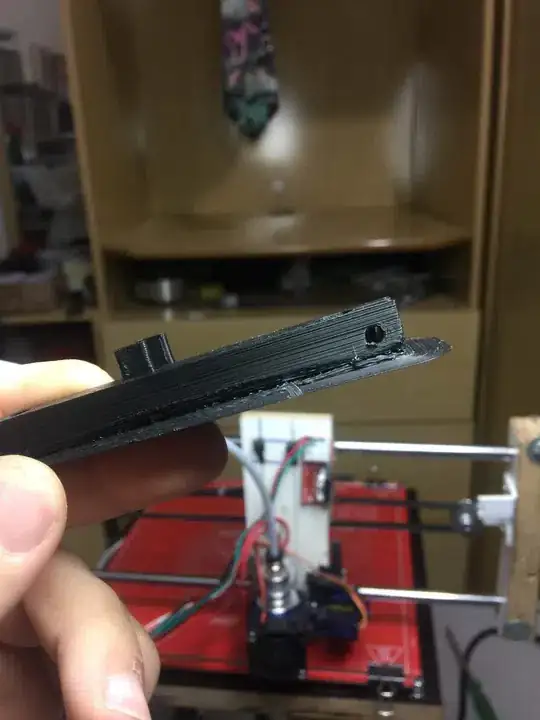

I'm having a frustrating problem with my recent built custom 3D printer so every single print I made, from the third layer, the nozzle is "rubbing" on the already placed filament. This results in a complete mess, melting the previous layers with the nozzle / new extrusions coming, getting malformed and out of precision forms, if I leave this happening, my Y-axis motor (bed) start to jump steps (by the force of nozzle friction to cold material). To stop that symptom, at the beginning of this, I have to raise the Z-axis by hand turning about 1/8 rotation of T8 fuse. By doing this, every rest of my printing runs peaceful, nicely, and beautiful.

I'm using Marlin firmware, the most recent version, and Ultimaker Cura. My nozzle size is 0.5 and I'm using Ultimaker Cura's Fine Preset (0.1 mm height)

My stepper motors axis are very well calibrated (X, Y, Z and Extruder). I tried:

- lowering and raising the print bed to get spaced or shrunken first layers to see if something helps,

- tried to change Z home offset on display,

- tried the

M206command to change the print zone of the Z-axis, - tried to change the first layer height on Ultimaker Cura,

but nothing seems to solve my problems.

Due to my lack of experience, I don't know what I could try to solve this frustrating issue. I already check and rechecked my mechanical structure and everything was fine solid and very well balanced and square.

From comment:

- Printing speed are 40 mm/s,

- Temps:

- Hotend: 220 °C;

- Hot Bed: 120 °C;

- I have also tried 110 °C,

- My Z-axis uses 800 steps per mm (1/32 micro stepping on DRV8825 at RAMPS).

I'm thinking about over extrusion but I have fine tuned my stepper, checked and rechecked for it and seems normal