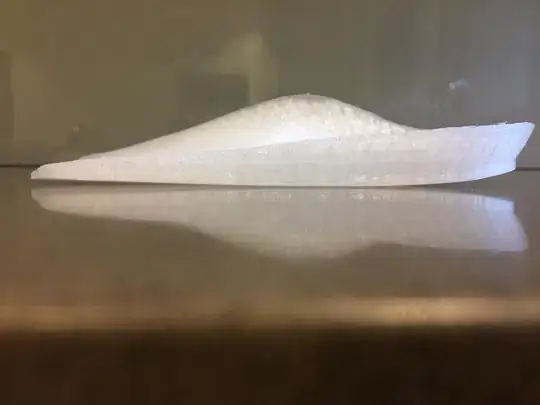

I am wondering if anyone can help me achieve a good 3d print using polypropylene. I am trying to print custom insoles for shoes and I'm getting some bad warping/lifting (see image).

Some details about the print and process:

- I have a Prusa i3 Mk2S with a Flexion extruder

- I am using what I believe is a good quality filament (Verbatim PP): https://www.verbatim.com.au/3d-printing/pp-filament/3d-pp-filament.html

- I am coating my hotbead with clear packaging adhesive (OPP tape) as per the manufacturers instructions. This appears to help quite a bit.

- Bed heated to 75 degrees. I tried 100 but got hit with the "Heatbed Thermal Runaway" error which I believe indicates that not enough voltage is getting to the bed heater.

- I've tried printing at 220 degrees and 170 degrees.

- I've tried enclosing the printer in a makeshift enclosure to reduce the speed that the material is cooling at.

- Other settings: speed 40mm/s constant, 0.2mm layer height, 20% infill, 3 top bottom and side layers.

The print takes about 5 hours and seems to stay down for an hour or two before starting to warp.

Does anyone have any suggestions of things I should try?