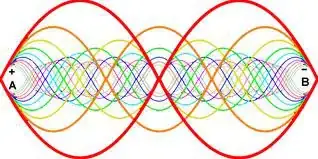

If an instrument sounds "right" has as much to do with how it is shaped as with how the material it is made of is layered - or not - as this changes it resonance. Let's take a few examples:

Metal, cast resins & hard woods all are very dense and contain (little to) no hollow spaces to dampen their resonances. This makes them the classic choice for making instruments, as just the shape changes the tune now.

Balsa wood is very very light and brittle, and it is very grainy, creating some hollowness inside the wood that should resonate, changing its resonance a lot.

I don't exactly know how the gourd is in its composition, but for percussion perposes, 3D prints are more on hollow side than on the hard wood side for low infill. Very dense (35%+) prints can have similar properties to solid resin casts, but this depends on the type of filament and printer used.

Let's look for a compromise!

From my own experience with musical instruments, there is a vougue of carbon fiber reinforced resin instruments in classics. In broad strokes, these were manucaftuered by casting resin over carbonfiber mats pressed in to a mold and then sanded and polished. In other terms, 3D printing of carbon fiber filament is around in the FDM scene, even if it highly abrasive and demands a nozzle like the ruby to print.

With the right interior design (that is, an almost hollow print that just contains struts that don't seperate cavities inside the print), a carbonfiber print could possibly be filled with resin and become a 3D-printed composite, granting a much closer sound to the gourd while providing extreme durability.

However, such a design will take many hours of work before the first print can start. Atop that printing carbon fiber is a specialty thing not many print shops can do or do regularily. And finally, the postprocessing of filling the "gourd shell" with resin is a very delicate process, followed by coating inner and outer layer and then tuning... I estimate such a thing to be at least as pricy as several real gourds.

Addendum

After some months and this question popping back up, I realised some more things that might be used in the design of this:

Thin shell, armored up. Think about this the following: Print a 2 or 3 shell thichk wall, that will be the most inner. Then reinforce it with resin and carbonfiber mats until the sound is right. This would allow to tune the gourd to some degree.

Solid print, slidified. You might take your model and print it solidly, yet in the design you could include tree like hollow spaces that are accessible from the outside. with a syringe. Pushing in resin via these holes would create veins of harder resin within the gourd, which might alter the tune and strengthen it.

Postprocessing. Ignoring the resin for a bit, you can also make a PLA gourd more stable by allowing it to cure in the oven for some time. I had some success baking it at about 100°C for about an hour. For mor information on how this changes the modulus of different materials, I suggest CNC Kitchen: Thin Walls & PLA Annealing and Changes in annealed PLA