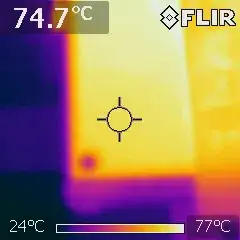

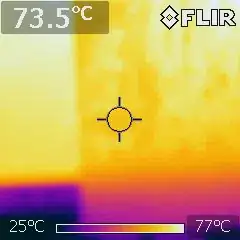

The aluminum plate is being heated by the heater element although I suspect the element does not encompass the entire area of the aluminum portion. There are going to be cooler spots on the aluminum but not enough to significantly affect the transfer to the glass.

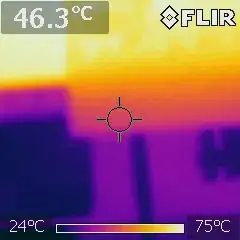

Once you extend the glass, without a corresponding extension to the aluminum and/or heater element, you are ensuring cooler spots. The glass will be surrounded by air, and begin to conduct some of the heat, certainly, but will also radiate a substantial amount.

If you are printing with PLA, you may get away with doing this modification. Very little of the heat from the aluminum will reach the glass.

A quick check shows the thermal conductivity of aluminum to be 205 W/m K compared to borosilicate glass at 1.2 W/m K in the range of temperature used for 3D printing. I did not research the rate of energy dissipation for the same range of temperatures, but if it's not too high (unlikely), it would still take forever for the unheated areas of glass to reach temperature.

Consider your extension to be an unheated bed and print accordingly.