After examining the guide (Kossel mini instrution by sintron technology_v2) and the printed parts kit, I came up with an 99.9% complete parts list. The lists relating to the effector and autoprobe mount maybe slightly incorrect:

##Parts List

###Listed by Printer part/section:

####Fasteners

#####BOTTOM VERTEX (QUANTITY = 3)

For each:

10 x M3 x 8 mm

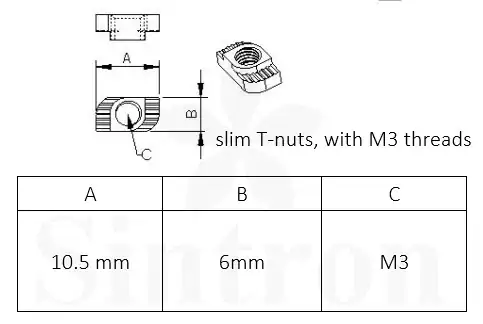

10 x M3 nut (T-nut)

#####TOP VERTEX (QUANTITY = 3)

For each:

5 x M3 x 8 mm

5 x M3 nut (T-nut)

1 x M3 x 35 mm

1 x M3 nut

1 x M3 washer

#####IDLERS (QUANTITY = 3)

For each:

1x M3 x 25 mm

4x M3 Washers

1 x M3 Nut

2x F623ZZ

#####MOTORS (QUANTITY = 3)

For each:

2 x grub

4 x M3 x 8 mm

1 x 16T/20T GT2 pulley

#####EFFECTOR

6 x M3 nyloc nuts

6 x M3 x 25 mm

4 (5?) x M3 x 16 mm <<==, or

2 (3?) x M3 x 16 mm <<==

2 x M3 x 20 mm <<== For the auto probe, if mounting the autoprobe directly on to a collar, above the hotend, and not on to the flange on the Sintron PLA collar

4 (5?) x M3 nuts <<==

2 x M3 x 8 mm <<== fan mounted to Sintron PLA collar

2 x M3 nuts <<==

1 x PC4-M6

Note: Some additional bolts are required for the mounting of the hotend. It is unclear what these are. See link.

#####VERTICAL CARRIAGES (QUANTITY = 3)

For each:

2 x M3 x 20 mm

#####ROLLER CARRIAGES (QUANTITY = 3)

For each:

2 x M3 x 10 mm

1 x M3 x 25 mm

3 x M3 nuts

3 x M6 x 25 mm

3 x M6 nut

2 x M6 washer (optional)

#####ENDSTOPS (QUANTITY = 3)

For each:

1 x M3 x 8 mm <<==

1 x M3 nut (T-nut)

3 x M3 x 8 mm <<==

3 x M3 nut

#####SPOOL

6 x 625-2RS Bearing (or 625zz)

5 x M5 x 20 mm

1 x M5 x 25 mm

6 x M5 nut

6 x M5 washer

(or 7 x M5 washer – there is a discrepancy between the kit (7) and the manual (6))

3 x M3 x 8 mm ?

3 x M3 nut (T-nut)

#####EXTRUDER

1 x M3 x 40 mm

1 x M3 x 8 mm

1 x M3 x ?? mm <<==

2 x M3 nut (T-nut)

1 x PC4-01

#####AUTOPROBE

Note: This is optional

2 x M2.5 x 12 mm

1 x M2.5 x 12 mm

2 x M3 x 8 mm <<== If mounting the autoprobe on to the flange of the Sintron PLA collar (if mounting directly on to a collar, above the hotend, then these are not required, and 2 x M3 x 20 mm replace 2 x M3 x 16 mm on the effector)

2 x M3 nuts <<== If mounting the autoprobe on to the flange of the Sintron PLA collar (if mounting directly on to a collar, above the hotend, then these are not required)

Safety Pin 2.5 mm

Spring 23.5mm

Terminal Block

1.5mm Allen key

Note: Some additional bolts are required for the mounting of the autoprobe, as well as the hotend. It is unclear what these are.

#####GLASS BED

3 x M3 x 8 mm ?

1 x M3 x 20 mm

4 x M3 nut (T-nut)

#####RAMPS

Note: This is optional, as mounting on the top will interfere with the spool

2 x M3 x 35 mm

2 x M3 nuts

2 x M3 nuts (T-nut)

###Total Parts:

####Fasteners

#####BOLTS

Size, Length, Quantity

M3, 25, (1×3)+(6)+(1×3) = 3+6+3 = 12

M3, 8, (10×3)+(5×3)+(4×3)+(4x3)+(3)+(1)+(2)+(3) = 30+15+12+12+3+1+2+3 = 78

M3, 16, 5

M3, 20, (2×3)+(1)+(2) = 6+1+2 = 9

M3, 10, (2×3) = 6

M3, 35, 3

M3, 40, 1

M6, 25, (3×3) = 9

M5, 20, 5

M5, 25, 1

M2.5, 12, 3

#####GRUB SCREWS

Size, Quantity

?, (2×3) = 6

#####NUTS

Size, Quantity

M5, 6

M6, (3×3) = 9

—

EITHER

M3, (10×3)+(5×3)+(1x3)+(1×3)+(5+2)+(3×3)+(1×3)+(3×3)+(3)+(2)+(2)+(4) = 30+15+3+7+9+3+9+3+2+2+4 = 90

OR

M3, (1×3) + (1×3) + (5+2) + (3×3) + (3×3) + (2) = 3+7+9+9+2 = 33

and

M3 T-slot nut, (10×3) + (5×3) + (1×3) + (3) + (2) + (4) = 30+15+3+3+2+4 = 57

—

#####NYLOC NUTS

Size, Quantity

M3, 6

#####WASHERS

Size, Quantity

M3, (1x3)+(4×3) = 15

M6, (2×3) = 6

M5, 6 (or 7)

####Bearings

Size, Quantity

F623zz, 6

625-2RS, 6

OR

625zz, 6

####Printed Parts

TBD

####Structural

3 x 2020 x 750/600 mm

9 x 2020 x 360/240 mm

####Electronics

1 x Arduino Mega 2560

1 x RAMPS 1.4

5 x Stepper drivers

3 x PCB mounted mechanical switch

3 x Stepper motors

1 x Extruder stepper

####Belts

3 x 16T/20T GT2 Pulley

GT2 belt (5 meters)

####Other Parts

Safety Pin 2.5 mm

Spring 23.5mm

Terminal Block

1.5mm Allen key

9 x Delrin wheels

9 x 696zz bearings

1 x PC4-M6

1 x PC4-01

###Uncertainties

The fasteners required for the following parts is, as yet, unclear

Effector/Hotend mount

Autoprobe mount

Additional Extruder holder screwpoint

###Assumptions

Hotbed frame mounts (assumed to be M3 x 8 mm)

Spool frame mounts (assumed to be M3 x 8 mm)

Endstops (four M3 x 8 mm are used, not just one)

See also Kossel - Sintron parts list.

I have a partial answer from the suppliers:

Hi

Good Day !

thanks for your contact.

we use M3 bolts + T-nuts .

i suppose the problem is , you don't have T-nuts , right ?

T-nuts is used for 2020 extrusion.

with warm regards.

james

I replied for a clarification of the length required:

Many thanks for the reply.

I have two types of 2020 extrusion, with differing profiles: one that

takes T-Nuts, and; one that takes regular hexagonal M5 nuts.

For the T-nut extrusion I have both M3 and M5 T-nuts.

However, the second type of 2020 extrusion takes regular M5 nuts.

Regular M3 nuts will not stay in place, unless I can find some M3 nuts

with a larger outer diameter, greater than 7 mm.

With respect to the M3 bolts, what are the lengths required? Are two

lengths used? One length to secure the endstop switch and holder to

the 2020 extrusion, and then another length to secure the remaining

three holes? Looking at the diagram in your build guide, it seems as

if only one bolt is used to secure the endstop switch and holder to

the frame, is that correct? Are any other bolts used to secure the PCB

mounted switch the the endstop holders.

I thank you in advance.

Best regards

I followed this up with a second email

Hi again James,

Following on from my previous reply.

Firstly, I have found that flanged M3 nuts will work perfectly, in the

extrusion that will not accept T-Nuts.

Secondly, what I really am looking for is a list of the lengths (and

dimensions) of the bolts used throughout the Sintron build. In

particular the endstop bolts. Rather than having to iteratively deduce

each bolt, a list of the bolts used would be very handy.

I thank you again in advance for your kind consideration.

Best regards,

I received a second reply from Sintron

Hello Friend.

for endstop . it's M3*8mm .

i am collecting the list of them for you soon.

thanks.

james