I have an E3D v6 1.75mm bowden.

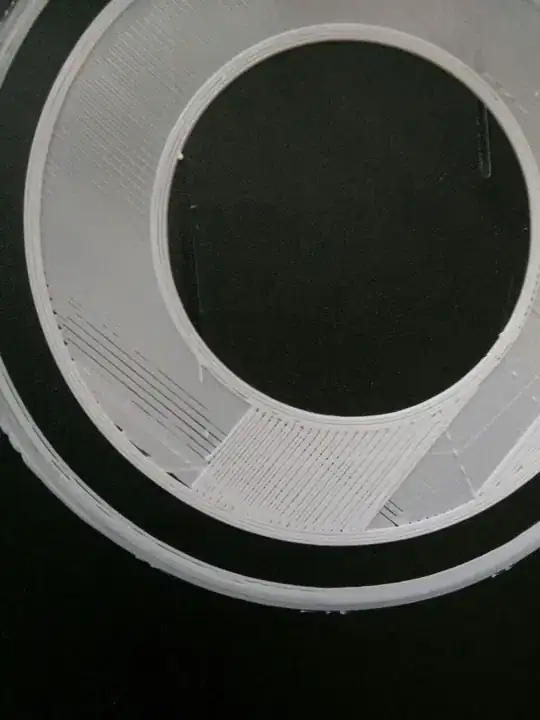

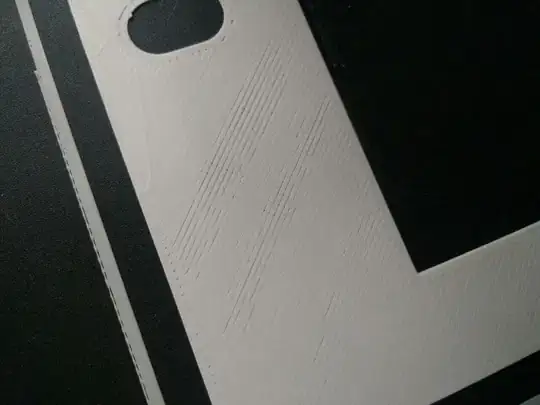

When I print, there is a gap between infill lines, and also when printing rectilinear/hexagonal infill lines seem to be pretty slim.

My settings:

- Slicer: Slic3r

- Nozzle size: 0.4mm

- Print speed: 30mm/s

- First layer print speed: 15mm/s

- Travel speed: 90mm/s

- Retraction length: 0.8mm

- Retraction speed: 40mm/s

- Extrude ratio: 1 (tried also with 0.48mm extrusion width, I remember it's the default S3D setting, so I gave it a try)

- Print temperature: 220 °C

- Material: PLA

Firmware settings:

- Firmware: Marlin 1.1.0-1

- Motion system: CoreXY

- Acceleration: 1000

- VMax X: 300

- VMax Y: 300

- VMax Z: 5

- VMax E: 80

- Xsteps/mm: 80.05

- Ysteps/mm: 80.05

- Zsteps/mm: 400

- Esteps/mm: 96.5

Disclaimer: I set Esteps/mm to 96.5 because I calibrated the printer as described here, so I'm 100% sure it's an accurate setting. Same for X,Y,Z steps. I printed a cube and calculated the real steps per millimeter, and it's accurate too. The extruder motor works, it's not the issue.

Here you can find some pictures that show what I'm trying to describe:

While printing I tried to release the extruder motor clamp and push the filament by hand: it extruded 1mm thick lines, so the extruder is not clogged and is perfectly capable of extruding the required amount of PLA.

Is it possible that the VMax E parameter is preventing the extruder motor to extrude properly? I mean, could it be that it's trying to extrude at a higher speed than the maximum allowed? Seems weird to me, because comments in Marlin's Configuration.h file say Default Max Feed Rate (mm/s) for that parameter, so if the limit is set to 80mm/s it should extrude just fine. If this is the issue, how should I solve it?