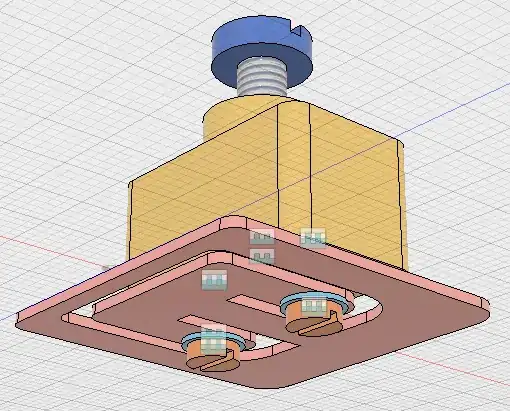

I am creating a 3D printed part which will act as an attachment between a plate (actually a strain gauge) with two M2.5 bolts and a 2kg load with a single M4 bolt. I wouldn't be happy with tapping a screw thread into the print itself so I want to try embedding the nuts into the print itself - so I'll pause the print at the right layer and then insert the nut and, hopefully, the print will resume.

I'm wondering is it worth also including washers? It's a major pain because, while a nut can be captive in a hex space, a washer is circular. So it needs to be glued down on insertion in case it rotates while the printer is printing on top of it.

For a 2kg load I don't believe the nut will attempt to pull through the part but there isn't a whole lot of support between the bore hole and the edge of an M2.5 nut though, only about 1mm.

Edit: I'll add an image of my initial design. The strain gauge is one of a set pulled out of a weighing scales (from Lidl, €5.99. You can buy each separately on the internet for 20 euro, so I saved 74 euro!). The gauge itself is mounted on the narrow "neck" of the gauge. The whole block will drop into a holder that grabs the outer edge of the gauge.