I recently purchased an FT-5 from Folgertech and finished assembly about a week ago. I have yet to accomplish a successful print. It seems like either the file is not being sliced correctly, or that it is possibly reading the G-code incorrectly. It will lay down the first perimeter layer of the part and then shift down the build plate a few mm in the y-direction, extrude another perimeter layer and then repeat. I have tried printing from an SD and through USB using Cura as the slicing software, with the same results.

- I have doubled checked the tightness on all of the belts and pulleys

- The Y-Driver was bad, initially so I swapped it with the spare on the board and it solved the issue.

- I have gone through the entire code on the Marlin V3 Firmware, and everything seems to look as it should.

- MKS Gen V 1.4 w/ Arduino Mega 2560

- I have tried using Arduino 1.6.5/1.6.6/1.6.7

- I calibrated the XYZ steps/mm

All of the mechanical movements and offsets seem to be correct. The printer connects to Pronterface without issue. It also homes fine from the machine and USB and moves where it should during these processes. Again, it seems to be that the issue is when it tries to interpret the G-code. I have tried multiple G-code files from different sources as well, still with the same luck.

If anyone has experience with similar issues or can offer any help, it would be greatly appreciated. I have no clue what could be going on!

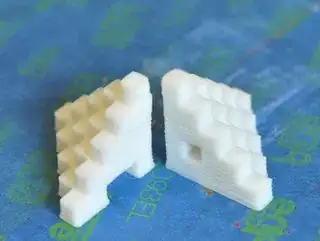

In red filament is my attempt to print the 5 mm calibration cube this morning, an example of how this calibration cube should look like is seen in the picture with the white calibration cubes.