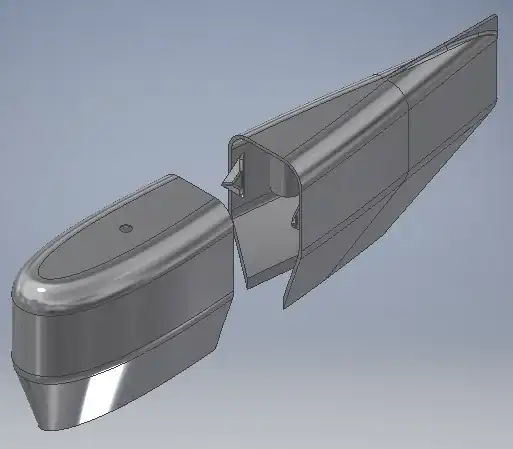

I have Ultimaker 2+ 3D Printer and I need to print a piece that doesn't fit within the build volume of the printer. Even though it would fit I'd still need to print it in two parts because I'll need to fit some equipment inside. I could use glue to put it together, but I'll need to remove the equipment later.

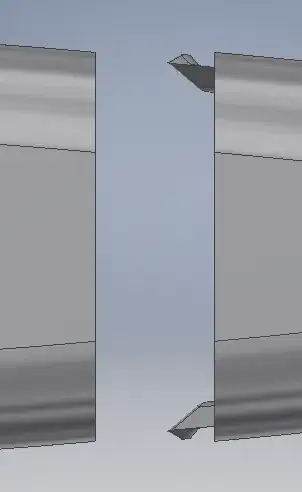

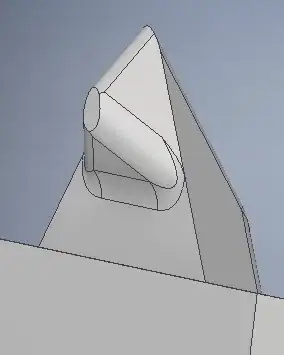

So I'm trying to find some feasible solutions how to attach/snap it together. The wall thickness is currently 3mm.

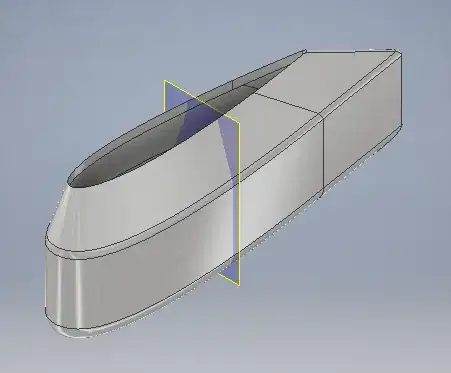

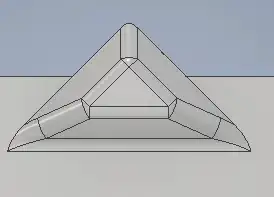

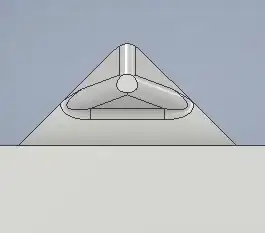

Plane for cutting the part.

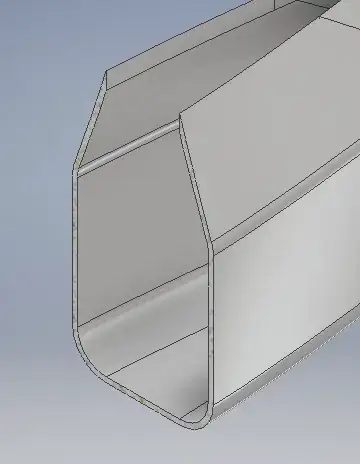

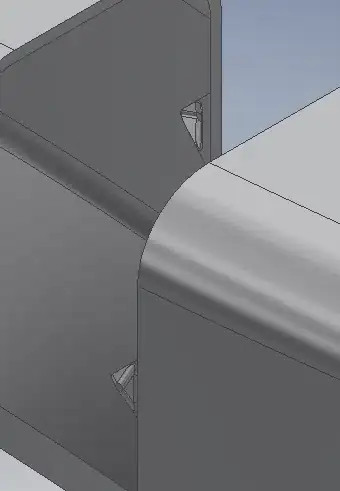

Cut cross section.