I have a Wanhao Duplicator i3 v2 (A.K.A. Maker Select, Cocoon Create).

My extruder got clogged: I noticed that it wasn't extruding, so I stopped my print, removed the fan, heatsink and the extruder motor and I saw that the clog is at the heater block level.

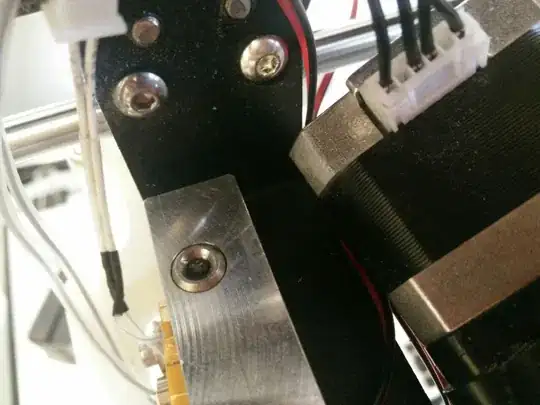

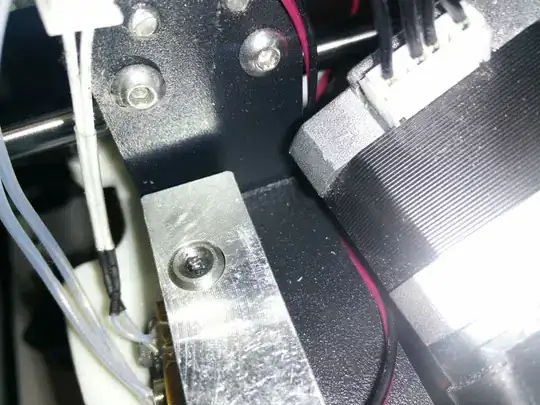

This is a what I have:

As you can see, there is some PLA clogged at the very beginning of the 1.75mm hole in the extruder block.

I can see there is something white inside (a stone? something that is not PLA?). I tried to heat up the extruder to 250°C and pushing with an hex tool but the block did not move.

I solved a lot of clogged nozzle issues with the cold pull method, it always worked like a charm, this time I tried too but as a result the PLA filament broke and the "stone" is still there.

Does anyone know if there is a way to unclog the extruder in this situation?

Do I have to change it?