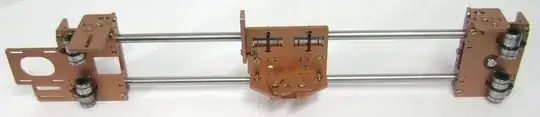

Here is the X-axis of the P3Steel:

The X-axis idler end of a P3Steel printer, employs an 8 mm diameter rod for the axle on which a 608zz bearing is mounted for the GT2 belt. This 8 mm rod is approximately 20 - 24 mm in length, with grooves at either end, for circlips.

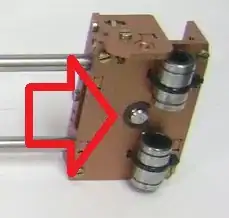

A photo of the assembled idler, with the rod and circlips highlighted:

My question is: Does this part need to be custom made?

The short rod didn't come with the frame kit that I purchased (nor was it listed in the parts list, or shown in the photo of the parts - so it not as if it was omitted with my order). I have searched on eBay for it, using various search terms, and I am unable to find one. As I was not trained in mechanical engineering, I am not sure if this part has a special name, or is it just called a "smooth rod, with grooved ends"? I have also done a fair amount of googling, and although I have found some people who have constructed this particular frame, no one makes mention of this axle, nor any difficulties in sourcing it.

I have contacted the supplier of the frame, Frame Prusa I3 P3Steel v4.0 +RODS, and I am awaiting a reply.

This missing part is holding up my build progress - I already have the 608zz bearing and circlips.

Additional images

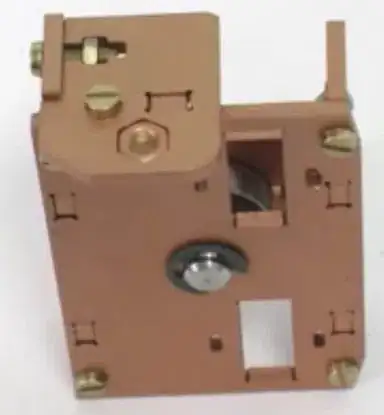

This image shows the "exploded view" and the 8mm rod can be clearly seen:

Here are images of the assembled idler, showing the bearing inside -

Front view:

Side view:

This images are a little blurry, as they are screen shots taken from the video, I3 Steel CORDOBESA con extrusor/with extruder.