This may be a result of an unlevel build plate (OP did not specify if calibration was done at time of writing).

If the area that is overlapping is higher (closer to the nozzle), the filament will be pushed down and around the nozzle as it extrudes in that area. This will result in excess filament overlapping unto other strands on the layer.

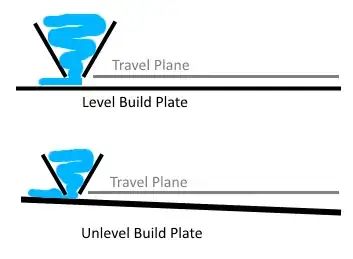

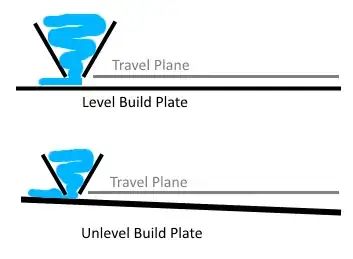

Please excuse my lack of artistic skills in paint, but the image below should illustrate what can happen when your build plate is unlevel:

Basically what it's trying to illustrate is that if the nozzle is closer than the expected layer height, the machine will continue to flow as if the nozzle is layer height away. This typically results in a larger layer width because the nozzle is essentially pushing material out of the way.

You will notice that as you go further to the right in the drawing, that your layer may begin to "thin out" because if the nozzle more than a layer height away, the filament "stretches" until it settles on the build plate, resulting in a thinner layer width.

Ideally, your nozzle will be parallel to your build plate at all points along the build space and the "Standoff Distance" will be equal to your layer height. So, you should see the top of your bead of filament at the same height as the bottom of your nozzle.