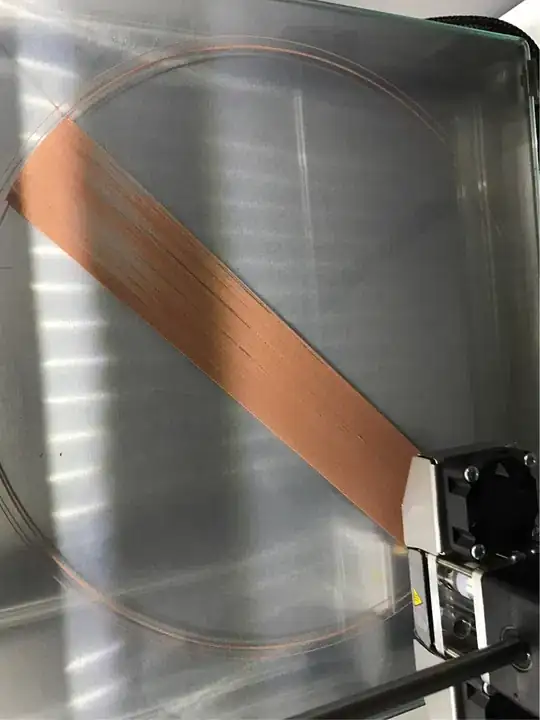

I switched out my 0.4 mm Ultimaker 2+ Nozzle the other day for the 0.25 mm and started using a ColorFabb Copperfill 2.85 mm filament. I am having some issues with it clogging and sticking to the bed for larger prints:

Current settings are:

- Extruder Temp: 230°C

- Flow Rate: 110% (increased it from 108% get more consistent output)

- Bed Temperature: 70°C

I thought it might be a calibration issue since I could see it skipping certain sections and slowly collecting excess material on the outer nozzle, so I recalibrated the bed but I still ended up with a blocked nozzle after about two hours of running. Not too sure if there are other settings I need to take care of. Any suggestions would be great!