As pointed out in the comments, what you are seeing could very well be related to lack of cooling:

You may notice that the irregularity in the print become more and more pronounced the further up you see. I believe this happens because the area that is printed is reduced gradually closer to the top, which in turn will give each printed layer less time to cool. (The frequent revisits of the hot nozzle will not allow the top layer to cool naturally.)

This problem is very common when printing models with small cross-sections, and are typically solved by:

- Installing additional print cooling fans (cooling the actual print, not the hotend/heat sink)

- Printing several items at the same time (to increase the cross-section)

- Reducing print speed (gives more time to cool, but might not work for very small models)

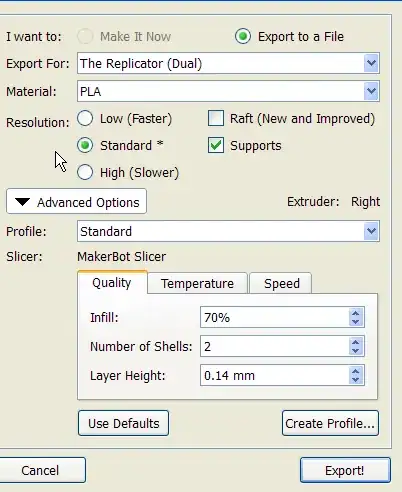

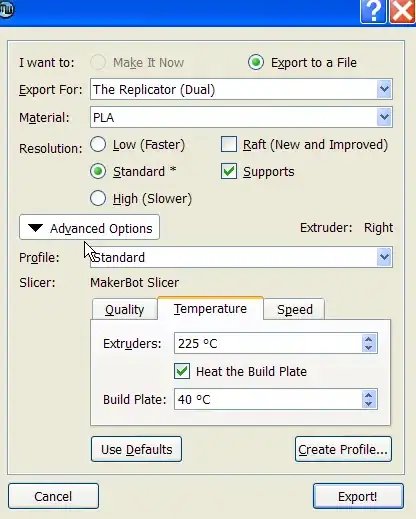

- Reduce printing temperature

If you can, installing additional fans and/or printing multiple objects at the same time are probably the most efficient solutions - in my opinion. However, either method would be worth exploring.

PS: When printing PLA, set your fans to full. ABS, on the other hand, does not like cooling.