I bought a 3D printer kit a few years ago, and it's been working pretty well, the kit was made with injection molded parts. -- It's similar to a Huxley, and through the years, it's started to turn into a repstrap as I've repaired it with non-printed parts.

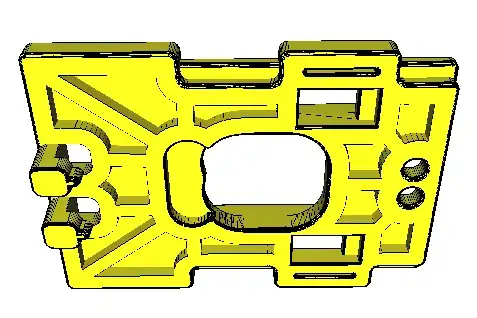

The parts are all open source and the STLs are provided by the maker, but they're optimized for injection molding, so instead of having flat surfaces, the surfaces usually have a lot of extra support going on -- here's an example of what I'm talking about:

Mind you, this is one of the simpler parts. -- But mostly I just want to clean these parts up -- make the edges flat by "filling in" these gaps (because: 1. it will print easier, 2. I can let my slicer handle the infill for me, etc.)

Currently, I've been using mostly TinkerCad and trying to make little rectangles and other shapes and boolean union them together to fill these gaps. But this is a lot of work, trying to get it just right without covering up important gaps or leaving pockets in the middle of the part is very time consuming and error prone.

Additionally, I'd like to be able to make minor beveled edges so that the parts are easy to peel up. -- I currently do this with boolean subtractions of a bevel shape I made (again, in TinkerCad).

Is there any software out there that makes these options easier? -- What's the easiest way to fill in these gaps and add beveled edges? -- I'm hoping to spend no more than 10 to 15 minutes per part. (Right now, it's hours.)