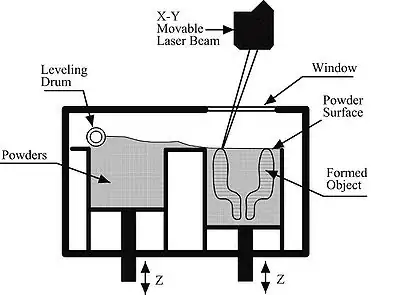

In my last topic I learned that Pronterface can control powder 3D printer provided that the slicer generate g-code for printer which is printing from metal. My question is as follows. Is there a slicer (open-source or other easily accessible), which will generate g-code that will be able to command the printer which operates on the following principle?

Asked

Active

Viewed 1,128 times

2

-

"Operating Principle" is not enough. Not all printers even take G-code commands to begin with. What *specific printer* do you have in mind? This determines the slicer you need to use. – Tom van der Zanden Oct 30 '16 at 18:37

-

If we go on the assumption that the thickness of the added powder for each scan is known (i.e. how far the RH piston moves per cycle), then all you need is to set the slice thickness to that value. This assumes further that the X-Y position commands sent to the laser positioner are properly oriented as well. – Carl Witthoft Oct 31 '16 at 15:36

-

I would suggest looking into how for Form2 printer slices. It has a laser that solidifies resin which is basically the same principal as the concept in your question. – Eric Johnson Nov 08 '16 at 20:26

-

"Metal" 3D printing is Additive Manufacturing. Do you have a 400W laser? – FeliceM Nov 10 '16 at 13:51

-

Your diagram looks as though you're referring to a "**Galvo**"-based laser system. Is this correct? If so, there are very few systems on the market that operate this way. My guess is that conversion from polar to cartesian and visa-versa would be controlled by the laser systems' controller and not the slicer. However, what you're suggesting as machine design should be handled through custom software, or at least open-source that focuses on this style of printing. I believe you'll find it difficult to find anything currently available in a working stage. – tbm0115 Nov 27 '16 at 01:46

-

Here's a [KickStarter campaign](https://www.kickstarter.com/projects/1467754733/saffire-galvo-based-sla-3d-printer-and-laser-engra) I just came across recently that has a similar concept, using a Gavlo laser. The product is called SafFire 3D Printer/Laser Engraver – tbm0115 Nov 27 '16 at 01:48

1 Answers

0

Laser SLS printers (3D Metal Printer) software requirements are very similar to SLA printers specially laser ones.

There are lots of different tools which you can use together.

You can use Lasershark 3D together with creationworkshop.

Also you can convert your source file to SVG or image files, using Slic3r, nanoDLP SLC2PNG or Asiga Stomp/Sleece. And convert SVG or Image files to toolpaths using cad.py, gcodeplot or any other freely available softwares.

Shahin

- 471

- 3

- 6