I recently changed the printhead on my DeltaMaker from stock to an E3D Lite6, and am struggling to get back to my original quality, reliability, and repeatability. I thought I had gotten the recipe pretty close to dialed in and tried a bigger print last night. It turned out pretty good in most respects except for where vertical structures rise up from the horizontal surface (and a retraction/stringing issue that I didn't think was but perhaps could be related).

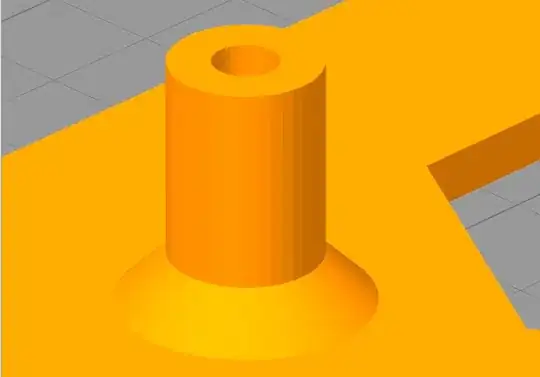

The screw hole mounts seem well-designed to me:

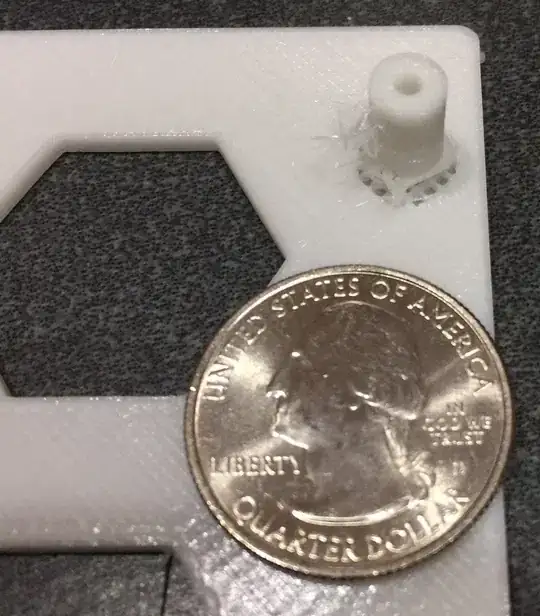

No 90 degree transitions - I would think this would be the least of my problems. But last night they had serious problems:

I haven't seen a problem like that before. Extrusion rate seems basically perfect - why does it look like it just stopped extruding around the perimeters?

I'm using PLA filament and Simplify3D 3.1.0 slicing. Settings:

- 0.35 mm nozzle, 0.40 mm extrusion width, 1.05 extrusion multiplier

- 0.15 mm layer height, 3 top, 3 bottom layers, 2 perimeter shells (maybe should try 3?)

- 30% infill, 60% outline overlap, 110% infill extrusion width

- Temp is 220°C (thermocouple wedged between nozzle and heater block reports about 206°C when thermistor says 220°C)

- Print speed is 2700 mm/min (45 mm/s)

Has anyone seen this issue before?

UPDATE: Increasing outline overlap from 60% to 90% almost fixes the problem (at least visually if not structurally) - there's just one small hole at the base of each structure. (I stopped the print a few layers after the problem layers do ignore the tops.)

Going to 99% (Simplify3D's max) would probably get rid of those last holes but I have to think that maxing out S3D's outline overlap setting to just barely make the print work means I haven't found or addressed the true root cause...