I'm looking for any idea of what could cause this problem. I'm printing (1.75mm PLA @ 220C) a 14cm x 14cm box, sliced with Simplify3D. Relevant settings are 3 bottom layers, 3 top layers, 3 outline/perimeter shells, and 15% orthagonal infill every other layer.

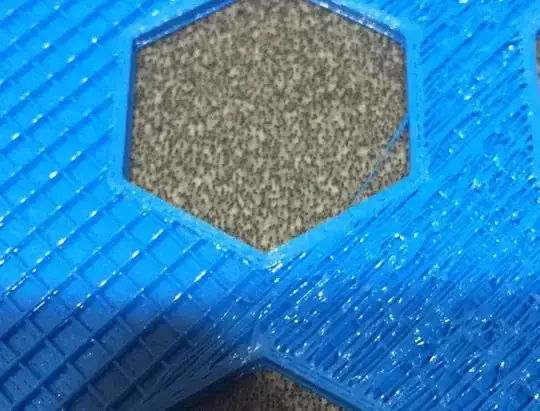

The first 3 layers print fine. Here's the first (bottom) layer after removing the print and turning it over:

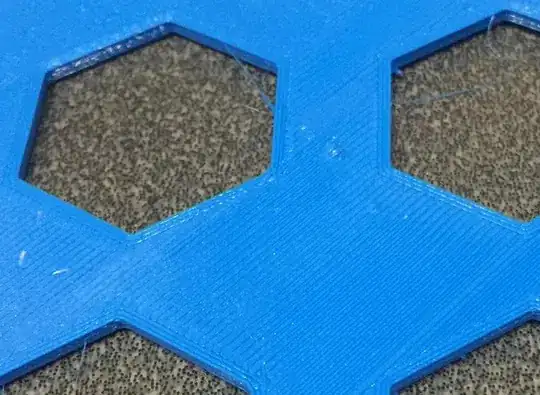

The infill (layers 4-10) also prints beautifully (see left side of photo below).

But the moment it starts printing the next layer (layer 11, the top layer of the bottom of the box), which should be solid fill exactly like layers 1-3, it starts underextruding and generally looking like crap:

The first time this happened, I figured the nozzle got clogged or the extruder gear started slipping. This is not the freshest PLA, so maybe it was a PLA quality problem. But the same thing happened at the same layer when I tried it again. And again. And again. As soon as I cancel the print I can have it extrude 5cm of filament and it's fine, no clogs...and if I immediately start another print it again perfectly prints layers 1-10. So it doesn't seem to be the extruder, the nozzle, or PLA quality. I can't imagine the "stress" of laying 7 layers of infill could screw up the next layer...

I just can't figure out how layers 2 and 3 could be basically perfect, but layer 11 is consistently a disaster, when they should be almost the exact same gcode (only a mm apart). I looked at the gcode and it's basically identical for layers 3 and 11, including same feedrate (G1 F2250).

This is on a DeltaMaker printer with a new E3D Lite6 hot end. Can add more details if needed, but basically I'm just looking for an idea of what could cause this.

Update: Just tried a different roll of PLA and got the same results.