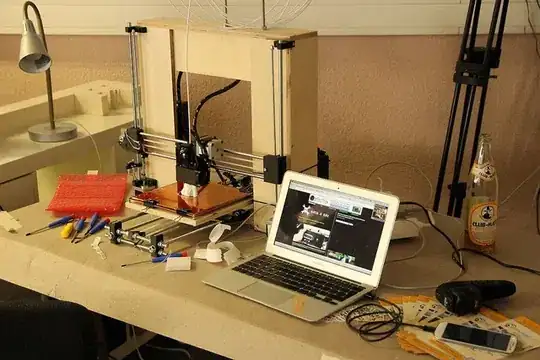

I've acquired all the parts to build a Reprap Prusa i3 rework, the only missing part is the frame.

I'm in doubt between a MDF cut (cheaper) or acrylic (more expensive), of course a cheaper one is my preferred option until I see any disadvantage on making it of wood.

I thought about variables like heat and humidity and the possibility of expansion/contraction of the frame, is this a valid concern? Will I have more precision buying the acrylic one or is it irrelevant?