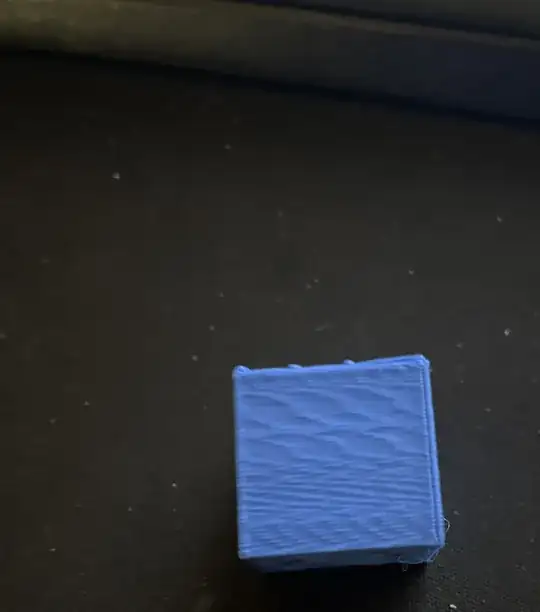

I have an Ender 3 Pro with the direct drive upgrade, aluminum extruder (The same problem happened with the plastic one), double-sided bed default black on one side and PEI on the other (Happens with both), aluminum adjustment knobs for bed with better springs, and upgraded spool holder with ball bearings.

Things I have done to try to fix this:

- Add aluminum extruder

- Upgraded spool holder with ball bearings

- Calibrated my E-steps

- Upgraded firmware

- Stopped using OctoPi

- Switched build surface (The only one that I could try that I have on hand is glass but that didn't work the last time I tried it)

- Tightened belts

- Printed calibration cube

- Printed temp tower

- Printed retraction tower

- Printed retraction speed tower

- Looked up YouTube videos

- Cleaned motherboard (There was dust in there)

Those all failed and I have no idea what this is or how to get rid of it, please help.

Settings:

- Layer height: 0.2 mm (I haven't tried a different layer height)

- Print speed: 40 mm/s (I have tried slower/faster)

- Nozzle temperature: 195 °C (I have tried higher)

- Infill density: 15 % pattern: cubic (I have tried different infill patterns and density)

- Cooling: 100 %

I'm afraid there is literally nothing else I could possibly do at this point except replace/tune mechanical parts, which I have tried.