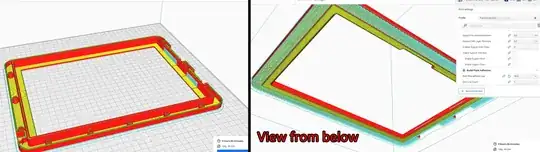

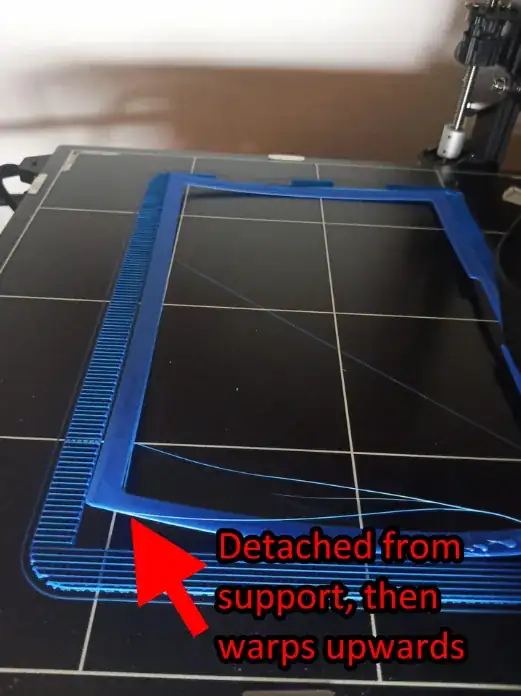

You are getting warping. It's unusual in this case, as your overall model is relatively low profile. It's the taller stuff that likes to warp.

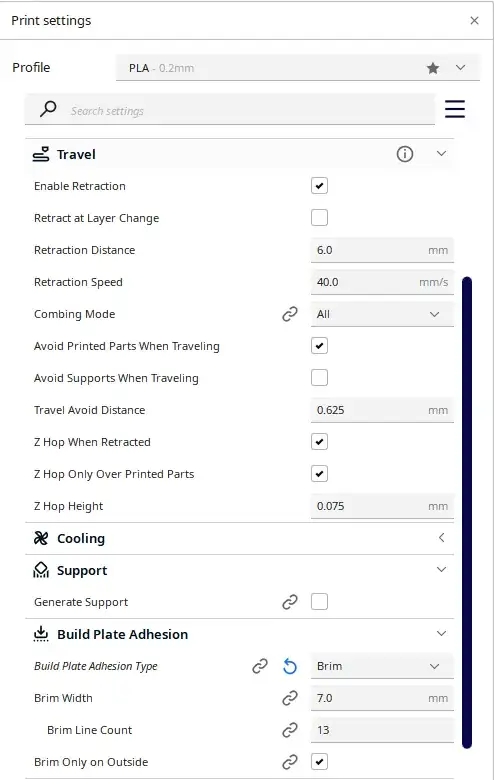

Consider to edit your post to include the layer heights and also the filament type and filament and bed temperatures. My first instinct is that your bed temperature is too low. There's little harm to be had by raising the temperature by ten degrees or so. Also if your slicer arbitrarily reduces the bed temperature after the first layers, disable that feature. There's no sense to set a good adhesion temperature on a print and later reduce it, yet I've seen slicer results that do just that.

Too cold filament by a substantial amount can also reduce the adhesion in combination with a too low bed temperature.

If you still run into adhesion problems, the Elmer's Purple Glue Stick works wonders.

With the new information comes new responses:

For ABS, 80 °C is on the low end for the bed, but may work. The extruder temp is really low for ABS. I run 250 °C for ABS. Also ensure some form of enclosure, even a cardboard box will help. I've accidentally fed ABS into a PLA profile. The results were surprisingly good, although warping was prevalent and some underextrusion was evident.

If you have a glass bed, you will very much want to use glue stick, as a release agent, not as an adhesive. ABS sticks really well to clean glass, well enough that it will pull fragments of glass from the surface!