How to configure PrusaSlicer to prevent printing in the air

You need either support or change the print orientation.

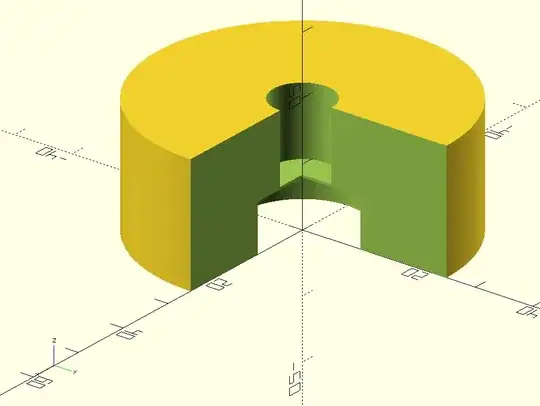

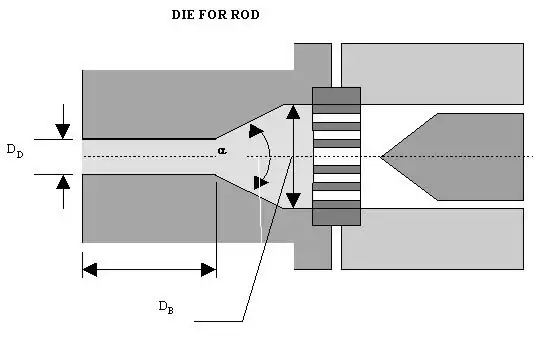

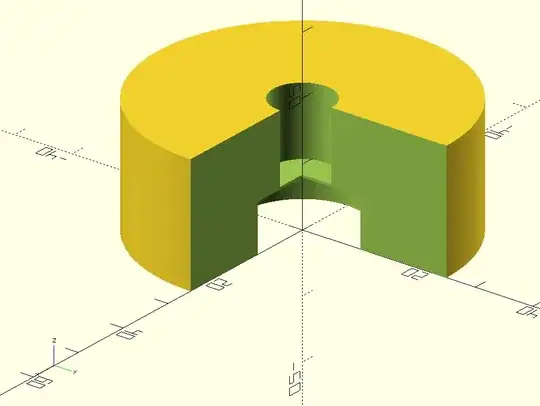

You cannot print into the air, you can however print lines on top of a prior layer with a certain overlap, or bridge a certain gap. E.g. (screw) holes are often covered with 2 layers over the screw hole so that you use bridging to print (the cutout shows that the hole has a bottom):

After printing you need to punch through the layers to open the hole.

Starting and stopping extruding in thin air will result in deposition of the extruded material on the location the nozzle crosses a prior layer (often seen when support structure pillars have fallen over).

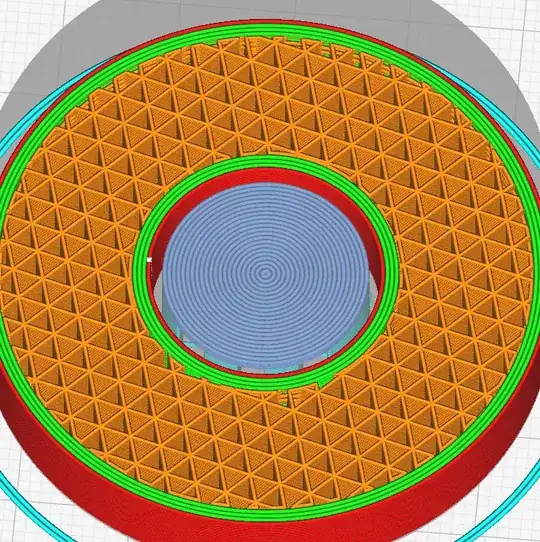

What is used frequently together with support in Ultimaker Cura is the option called Enable support roof, this will create a dense top layer on top of the support interface which allows for pretty good bottom surface of the overhang.

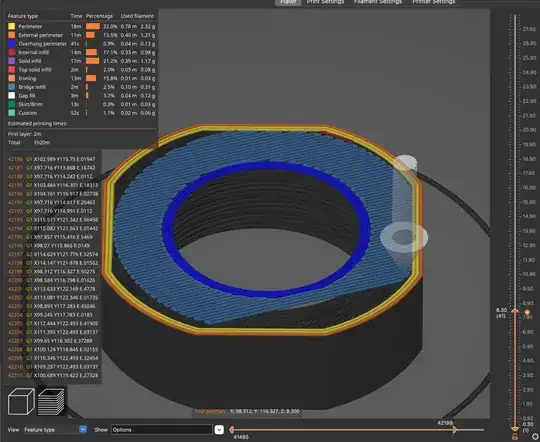

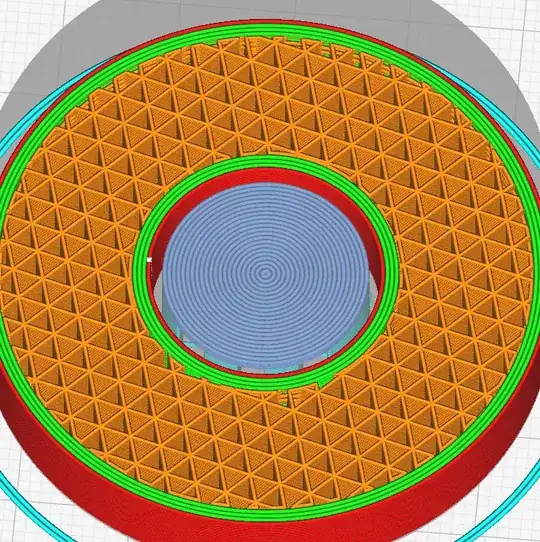

This e.g. results in the following slice:

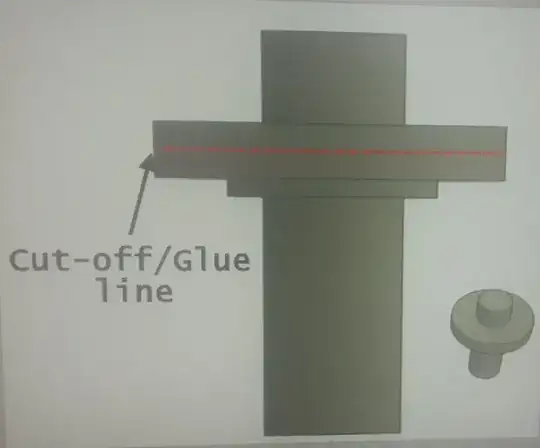

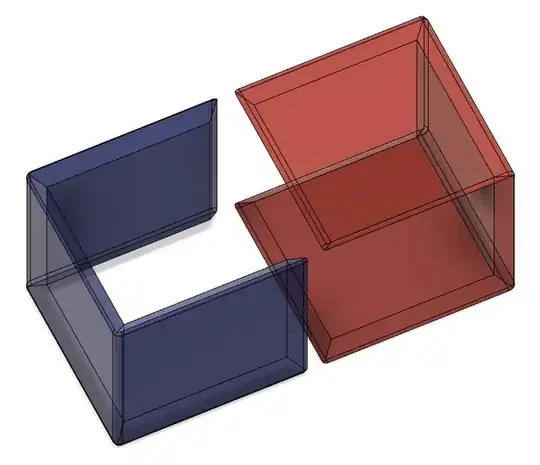

When applied to a recently printed flanged tube you see that the bottom surface is pretty good (note the concentric lined top surface, first image shows the product with support, second image, on the left a view of the bottom above support layer and right the support with roof layer):

How to configure PrusaSlicer to prevent printing in the air

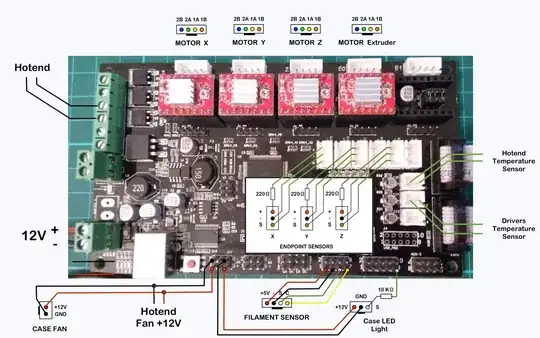

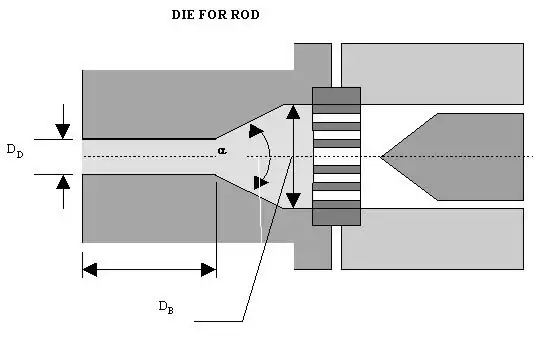

In PrusaSlicer you should be able to something pretty similar with Interface pattern spacing set to zero: