I am trying to create a two-piece snap-fit or joint using a 3D printer (Resin). After that, I plan to coat the joint with a conductive spray and create an electrical connection when the two pieces are joined together.

Has this been done before? Are certain types of joint mechanism recommended?

I will probably use carbon spray because it is cheaper than others. However, after the spray dries it can start to flake and thin, so I might need a couple of rounds of coating or something else. Any tips are appreciated.

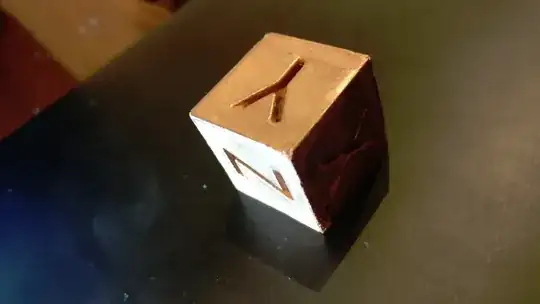

However, more importantly is the joint mechanism - this is what I had in mind:

The signal would be a DC current only, in the µA range and the targeted resistance would be less than 20 Ω.

Can this work? If not, what are my alternatives?