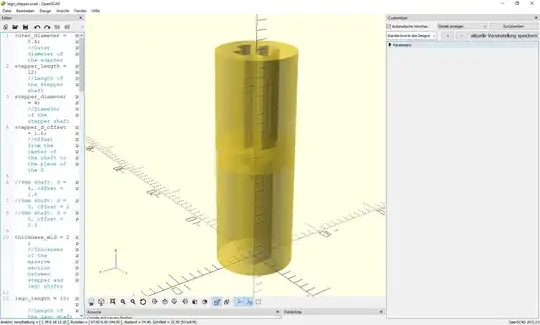

OpenSCAD would be well suited for creating something made up of relatively simple shapes, where different dimensions are needed for some parts of the shapes - like the diameters and offsets of your stepper motor shafts.

A solution in OpenSCAD could look something like this:

outer_diameter = 8.5; //Outer diameter of the adapter

stepper_length = 12; //Length of the stepper shaft

stepper_diameter = 4; //Diameter of the stepper shaft

stepper_d_offset = 1.6; //Offset from the center of the shaft to the plane of the D

//4mm shaft: d = 4, offset = 1.6

//5mm shaft: d = 5, offset = 2

//6mm shaft: d = 6, offset = 2.5

thickness_mid = 2; //Thickness of the massive section between stepper and lego shafts

lego_length = 10; //Length of the lego shaft

lego_diameter = 4.9; //Outer diameter of the lego shaft

lego_internal_width = 1.9; //Width of the slots for the shaft

lego_corner_radius = 0.5;

cutout_size = lego_diameter;

cutout_translate = cutout_size / 2 + lego_internal_width / 2;

$fn = 128; //Accuracy / resolution of circles

eps = 0.01;

module fillet_square(width, radius) {

translate([radius - width / 2, radius - width / 2, 0])

minkowski() {

square(width - 2 * radius);

circle(radius);

}

}

color(0,0.5)

union(){

linear_extrude(height = stepper_length + eps) {

difference() {

circle(d = outer_diameter);

difference() {

circle(d = stepper_diameter);

translate([0, stepper_d_offset + stepper_diameter / 2, 0]) {

square(size = stepper_diameter, center = true);

}

}

}

}

translate([0, 0, stepper_length]) {

linear_extrude(height = thickness_mid) {

circle(d = outer_diameter);

}

}

translate([0, 0, stepper_length + thickness_mid - eps]) {

linear_extrude(height = lego_length + eps) {

difference() {

circle(d = outer_diameter);

difference() {

circle(d = lego_diameter);

translate([cutout_translate, cutout_translate, 0]) {

fillet_square(cutout_size, lego_corner_radius);

}

translate([cutout_translate, -cutout_translate, 0]) {

fillet_square(cutout_size, lego_corner_radius);

}

translate([-cutout_translate, cutout_translate, 0]) {

fillet_square(cutout_size, lego_corner_radius);

}

translate([-cutout_translate, -cutout_translate, 0]) {

fillet_square(cutout_size, lego_corner_radius);

}

}

}

}

}

}

You can then export your .stl file (or any other format) for 3D-printing from OpenSCAD.